by Christopher Pritchard and Fred Steinhauser, OMICRON electronics, GmbH, Austria

At the end of 2024, the Swiss Broadcasting Corporation will switch off the FM radio stations and move on to DAB+. And even in the conservative field of power systems protection, automation, and control, things like electromechanical relays, that implement much of the function analog, are fading out.

In most cases, the quantity to be processed is digitized close to the process by an A/D converter, and we go purely digital from there. As soon as information is transmitted over a digitally coded communication link as used with IEC 61850, we are entirely in the digital domain and “analog” does not apply anymore.

Nevertheless, the term “analog” is still often used incorrectly when “measured” values are actually meant, in an attempt to outline the fact that the value may take on any value from within a range. Of course, in the digital domain, “any value” is impossible since digital values are quantized. The smallest amount of two adjacent digital values can differ from each other is called the resolution. But this quantization is not an issue, as long as the resolution is sufficiently smaller than the measurement uncertainty, which is the case in well-designed systems.

So, bottom line, there is almost no place anymore for the term “analog” in today’s systems. And as outlined above, when still used it is often in the wrong place.

In an era where protection, automation, and control (PAC) systems are already embedded within digital technologies, the imperative for a digital transformation may not be immediately apparent. However, the necessity for such a transformation becomes clear when considering the challenges faced by utilities today. These challenges include the need to manage extensive grid expansions and the struggle to compensate for the scarcity of skilled labor. Digital transformation, in the context of operating a PAC system, is about leveraging the existing digital infrastructure to its fullest potential to enhance user experience, optimize efficiency, and minimize errors.

Digital transformation is not a mere continuation of digitization but a comprehensive reimagining of how PAC systems can be operated more effectively. In this article we will examine how time synchronization, communication networks, documentation, IEC 61850 engineering and process bus and so on can change our operation for more efficiency. (Figure 2).

As the PAC landscape evolves, so too must the skills of those who manage and operate these systems. Therefore, we will also investigate the digital upskilling of the workforce as a crucial aspect of digital transformation.

Time Synchronization

Electrical power engineers are aware of clocks that we could consider to be “analogously synchronized” (or maybe more accurately: “syntonized”): the clocks driven by synchronous motors, following the frequency of the power network. But this must almost be seen as an exception because most systems to synchronize clocks have been digital for more than a century, forwarding a synchronization event from time to time.

A prominent example were the clocks in railway stations, which received a synchronization pulse from a master clock once a minute. This synchronization information was distributed over a dedicated infrastructure, making this applicable only in a small number of cases.

As a benefit of the always improving communications technologies, we have obtained means to distribute time with always increasing accuracy via communication networks. This started with NTP (Network Time Protocol) and evolved into PTP (Precision Time Protocol), which delivers the so-called µs-accuracy that we need for time stamping the events in the Digital Substation. The next evolution of this kind is White Rabbit, which pushes the timing accuracy by some more orders of magnitude.

Communications Networks

Already morse code was a form of digital communication. Sound or no sound, longer and shorter sounds, all these were distinct states, something that we could represent with two bits. Then came the early form of voice telephony, where the air pressure modulation caused by human speech was really transmitted by proportionally changing electrical currents. This was truly analog communications technology, but in the big picture, it was an outlier. Already starting in the 1960s, it was replaced by the digital PCM telephony system. From the 1970s onwards, telephone modems established data links between computers by beeping data through the telephone system. The original digital information was converted back and forth between digital and analog on its way through the telephone system, only because the human interface was analog. Eventually, technologies like ISDN brought digital data services even to homes around 1990. Then came DSL, showing us the potential and bandwidth of the copper wires in our telephone systems.

At the physical level, a carrier, which is always an electromagnetic wave, is somehow modulated according to the digital input. The modulated carrier propagates on the physical layer in the analog domain to the receiving end, where the digital signal is recovered.

Smart coding and redundancy provide an efficient and reliable use of the physical communication medium, and checksums further guarantee an extremely low probability of undetected transmission errors.

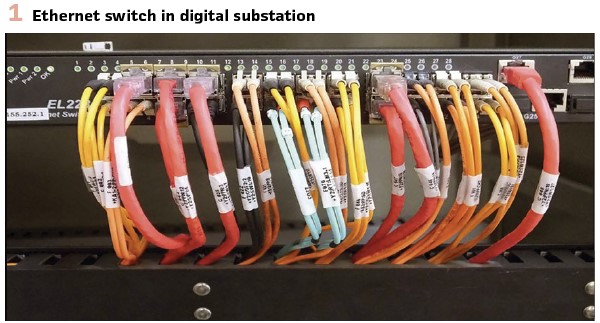

In private homes, offices, factories, as in Digital Substations, Ethernet has established itself as the standard computer networking technology. It utilizes various media at different speeds, covering all the needs of modern LANs (Local Area Networks). WAN (Wide Area Network) techniques extend the reach of communication and the scope of applications. (Figure 1).

How can we make more use of digital communication to improve our efficiency? Protection schemes that use communication are common for transmission systems, but rare in the distribution grid. Meanwhile, protection engineers face difficulties from the increasing number of inverter-based resources (IBR) that connect to the distribution grid. They have to adjust familiar protection principles (overcurrent and distance protection) for the non-physical behavior of IBRs.

Principles that do not depend on the source behavior like differential protection would make the engineering of the main protection easier and also provide better performance. In the past, proprietary direct fiber connections restricted the application of differential protection or other communication assisted principles.

New and open communication standards like Multiprotocol label switching (MPLS) are setting up dedicated paths across networks without relying on a standard routing process, therefore enabling the utilization of WAN.

Digital Documentation

The evolving topic of the Digital Twin has brought other aspects to our attention. Depending on the focus, it is interpreted differently anyway. When coming from the power systems protection side, the close-to-realistic simulation of the behavior of protection devices might be the entry point into this topic. The actual firmware of the real devices is executed on virtualized hardware. Of course, this takes place in the digital domain.

But the term is also applied for a much wider scope, to an encompassing model of a whole substation, persisted as machine-readable digital information in an asset database. Representing this information in a classical form of documentation (lists, drawings, or schematics on paper or as PDFs) is no longer feasible. The amount of data is simply too large to be “printed” and the content is too dynamic, so maintaining it is only possible in the digital database.

For browsing/inspecting/searching this information by humans, appropriate tools are required that present a comprehendible subset of the information in context (e.g., troubleshooting). Typically, this will be a specialized viewer running on a computer/tablet.

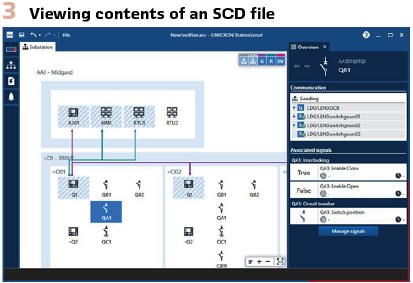

Analogously, this applies to the IEC 61850 system configuration persisted in the so-called SCD files. Also here, any attempt to bring the contained information to paper is futile. The SCD file itself is the documentation and using and viewing this information is facilitated by tools, presenting the information related to the context.

By adding as much information as possible to the digital documentation, such as the SCL file, and using suitable tools, more efficiency can be achieved. A common data source eliminates the redundancy of assets in different tools and paper templates, reducing transcription errors. In case of a maloperation during a standby service, appropriate tools can already read the configuration and perform a system verification, without the need for turning pages in folders and beeping wires. (Figure 3).

Automated Workflow

The machine-readable data in the asset databases and the configuration files are the precondition for the automation of the workflow. Processes are automated by using software, and software must be fed with data, much more data than a human can enter at a prompt. When looking at IEC 61850 Digital Substations, designs can be derived from rules and templates, delivering an initial SCD file with a populated substation section. Augmented with placeholder IEDs (Intelligent Electronic Devices) for hosting the functions (logical nodes), the communication interfaces of the PAC system can be already simulated, and first tests can be performed. In the implementation phase, the placeholders are replaced by real IEDs, and testing will be intensified, often with a mixture of simulated and real IEDs, until the commissioning phase, where the entire system consists of real instances and simulation is minimal. In all these phases, the final stage will be approached iteratively, and the data are gradually adopted and improved. The consistency of the database can be only assured by proper tools and automation.

To facilitate the automation of the workflow and providing machine readable data, related extensions of IEC 61850 are under development. To name are the technical reports IEC 61850-90-30 (Guidelines for IEC 61850 Function Modeling in SCL) and IEC 61850-7-6 Ed2 (Basic Application Profiles), which introduces the Application Specification Description (ASD).

Sampled Values as Digital Lighthouse

The most obvious sign of the shift to digital in modern PAC systems is the application of IEC 61850 Sampled Values (SVs). Their use is often seen as the deciding indicator to call a Digital Substation a “Fully Digital Substation.” It implements the concept of digitizing the measured values close to the process, in our case within the feeder/bay as close as possible to the voltage and current sensors delivering the measured values. The merging units perform the function of the A/D converter. The communication link over the so-called process bus eliminates the last piece of analog signal transmission within the PAC system. But even before using Sampled Values, an A/D conversion took place in the front-end of the digital relays that have been in use for decades now.

As SVs can be transmitted over a communication network, enabling all sensor data to be sent to a central instance for processing and analysis, they are the enabler for many transformative innovations.

A centralized protection and control (CPC) system offers several benefits in the context of power system operations. It simplifies the overall system design by consolidating multiple relays into one device, thereby reducing system complexity. This consolidation leads to a reduction in the number of protection devices, which in turn minimizes installation time, maintenance, testing, and costs while enhancing protection.

A centralized protection system can facilitate the implementation of advanced protection schemes that leverage the full potential of the digitized PAC system. For instance, applying a low-impedance busbar differential scheme is just a matter of configuration, thereby enhancing the reliability and efficiency of the protection system. Lastly, a centralized protection system can also offer substation-wide disturbance, fault, and event recording. This facilitates post-event analysis and contributes to improving reliability.

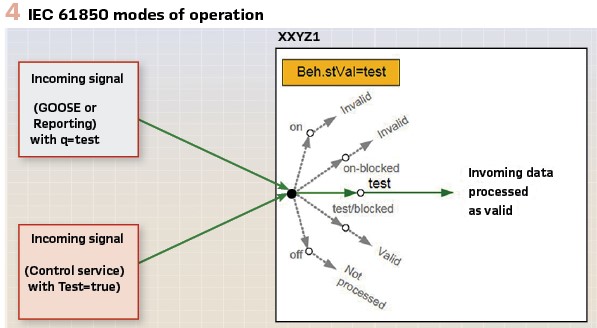

Until today, the common practice is to send highly skilled professionals to a substation to perform different kinds of tests throughout the lifecycle of a substation. Onsite, the professionals have to short-circuit the current transformers (CTs) and isolate binary contacts e.g. the trip contact before they can inject analog signals. Instead of sending valuable professionals around the country exposing them to electrical hazards, we can reduce the onsite testing by introducing remote testing. In substations with process bus, IEDs can be isolated via communication configuration – no physical interaction is required.

During commissioning analog injections are still required, for example for testing the CT circuit. But maintenance testing and re-commissioning due to setting changes or firmware upgrades could be performed remotely. (Figure 4).

To reduce operational efforts even more, we can utilize the fact that all process quantities are available at one location to establish a monitoring system. With that in place we can reduce routine testing effort and at the same time prevent maloperations. Such a monitoring system can check primary asset health as well as the functional integrity of the PAC system communication.

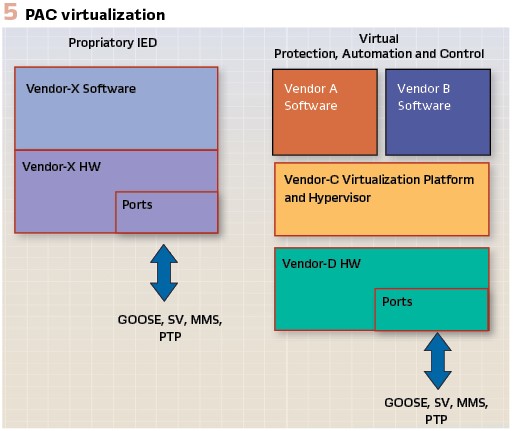

Virtualization

Virtualization allows multiple virtual entities to share the same physical resources, such as CPU, memory, disk space, and communication bandwidth, without interfering with each other. Virtualization originated in the 1960s, when IBM developed the first virtual machine (VM) technology for its mainframe computers. VMs enabled multiple operating systems and applications to run simultaneously on the same hardware.

Today, virtualization is a state-of-the-art technology in IT systems, with many benefits. Virtualization reduces hardware costs and maintenance efforts by consolidating multiple physical machines into virtual ones. Virtualization can also improve performance, availability, and reliability, by enabling failover, backup, and recovery of virtual machines.

Virtualization can also facilitate migration, portability, and interoperability, by allowing virtual machines to move across different platforms and locations.

If PAC professionals envision the CPC of the future, they often envision a virtualized system where all functions of a PAC system are running as software within a virtual environment on a generic server hardware. Such a software defined system has numerous benefits. It allows for quicker deployment, an open environment within the substation for creative solutions, and robust and standardized patch management. (Figure 5).

Automated Decision Making

Everyone is talking about the fact that electrical energy systems are becoming increasingly complex. The amount of information that must be considered when making decisions, e.g., during a critical situation in the power network, exceeds the capacity of a human, no matter how experienced and skilled she may be. The causes of a problem and the consequences of an action may not be obvious to a human network controller. And the expected outcome of a corrective action may depend on circumstances that vary quicker than the controller is aware of. To master this adequately, automated decision making must be used. The buzzword of today would be “artificial intelligence,” but any heuristic or algorithm to facilitate such kind of decision making is to be considered.

We should not distract ourselves by the argument that these automated systems could not find the perfect solutions for the problems, driven by the naive and self-overestimating assumption that humans could do that. To adequately master a situation, a solution close to the best one will be good enough. There might not even be a clear criterion for the best solution. The automated system can assess several possible actions and their consequences in a short time. By selecting the “best” of a set of possible solutions, a well-designed decision-making algorithm will deliver one close enough to the optimum. Or one that is at least as good as the one taken by the human controller.

Challenges

As with all new technologies, the new opportunities are accompanied by new challenges. Many of them, as the conditioning and A/D conversion of measured values have been mastered for decades. With the introduction of digital communications on a large scale, the topic of cyber security came into play. It is perceived as a relatively new challenge, as the first serious incidents started to appear in this millennium. The cyber security issue is not so much a consequence of digitalization itself, but of the encompassing accessibility of the systems through communication networks. Due to this, the topics are intertangled and we cannot get away from it when we talk about digitalization.

Of course, cyber security must be mastered and there are practices available to do so. Most incidents could have been avoided if the available means had been actually applied. Basic cyber security hygiene would have been sufficient in most cases, as only few targets are important enough to become subject to individually crafted attacks.

The solutions applied are evolving, but we may remember how assets were protected from criminal intent and unauthorized access in the conventional, physical world: by fences, locks, and concierges. And typically, there were not individual fences, lock systems, and concierges for individual assets on a premise, but all of them were protected by the same security perimeter.

This concept may be well carried over to the cyber security domain: overall, it does not make sense to have individual solutions for any application or connection to an asset. Having individual secure access methods for any brand of PLC, protection relay, or transformer monitoring system will end up in an inscrutable pile of access methods and credentials. This must be solved with an encompassing security infrastructure that provides a safe habitat for all deployed applications. This is a top-level responsibility for asset management, IT, and OT.

Teams and Know-How

Digital transformation in the PAC sector is a strategic imperative that goes beyond mere digitization. It is a holistic approach that encompasses technological, operational, but also cultural shifts within utilities.

The job profile of PAC specialists today is already very different to the one 10 years ago. While PAC specialist still need a sound knowledge of the applied technology, they will have to work in multidisciplinary teams with other experts, such as network engineers, and software developers, to ensure the reliability and resilience of the power sector.

Training and development programs are vital in equipping personnel with the knowledge and tools necessary to thrive in a digitally transformed environment.

The expansion of the network and the lack of professionals will make it necessary to constantly revise the processes for efficiency. PAC specialists will have to adapt to changing requirements, learn new tools and methods, and collaborate with other experts to optimize the system operation for performance and security.

Outlook

Today’s PAC systems are already digital. As the power sector faces increasing complexity and uncertainty, utilities need to leverage the full potential of digital technologies to enhance their performance, reliability, and resilience. Digital transformation is not a one-time project, but a continuous journey that requires constant innovation, adaptation, and collaboration.

This article only provided a very high-level overview of the main aspects and benefits of digital transformation in PAC systems, as well as the challenges and solutions involved.

Biographies:

Christopher Pritchard Dipl.-Ing. (FH) was born in Dortmund / Germany. He started his career in power as an electrical energy technician. Christopher received a diploma in Electrical Engineering at the University of Applied Science in Dortmund in 2006. He joined OMICRON electronics in 2006 where he worked in application software development in the field of testing solutions for protection and measurement systems and is now the responsible Product Manager for system-based testing solutions.

Fred Steinhauser studied Electrical Engineering at the Vienna University of Technology, where he obtained his diploma in 1986 and received a Dr. of Technical Sciences in 1991. He joined OMICRON and worked on several aspects of testing power system protection. Since 2000 he worked as a product manager with a focus on power utility communication. Since 2014 he is active within the Power Utility Communication business of OMICRON, focusing on Digital Substations and serving as an IEC 61850 expert. Fred is a member of WG10 in the TC57 of the IEC and contributes to IEC 61850. He is one of the main authors of the UCA Implementation Guideline for Sampled Values (9-2LE). Within TC95, he contributes to IEC 61850 related topics. As a member of CIGRÉ he is active within the scope of SC D2 and SC B5. He also contributed to the synchrophasor standard IEEE C37.118.