PAC World: When and where were you born?

M.A.: 1953 in Teaneck, NJ, USA.

PAC World: Where did you go to school?

M.A.: St. Joseph’s grammar school, Demarest, NJ; Bergen Catholic HS, Oradell NJ; Cornell University (BSEE; MEEE); Polytechnic University of NY – MSEE.

PAC World: What were your interests while in school?

M.A: Electricity and things mechanical.

When I was about 5, I had a toy motor with two wire leads on it from taking apart one of my toys. Obviously, it should work when plugged into a wall outlet…. I am still here.

PAC World: Do you remember anything from your childhood that you think contributed to you becoming an engineer?

M.A.: My father was an Electrical Contractor and I worked with him – starting from when I was 6 years old. We would go to a job site where the door was locked. We would typically find an open window. I would be placed through the window and then go and open the door. My father was a great patient teacher and I learned much from him.

PAC World: Was there a person that had the most influence on you when you were growing up?

M.A.: Clearly my father and his influence of being involved with electricity. I knew when I was 6 years old that I wanted to learn about electricity.

PAC World: When and why did you decide to continue your education?

M.A.: Referring to my Master of Engineering degree – I was not ready to leave school and my 5th year did consolidate much of my previous 4 years of college. Pursuing my Master of Science degree came about because I had Drs. Phadke and Thorp as mentors as well as a MS in Mathematics – Ted Hlibka – who encouraged me….and the world was going digital, and I wanted to be a part of it.

PAC World: How did you choose the university to go to?

M.A: I wanted Power System Engineering and Cornell had a good reputation in this area. Additionally, Brooklyn Poly had courses in Power and Digital Systems.

PAC World: Did you study electric power systems or protection while in college?

M.A.: Power Systems and some protection (I learned about Zones of Protection).

PAC World: Was there any professor that helped you select your future career path?

M.A.: I met Dr. Arun Phadke on my first day on the job at AEP as a co-op engineer and a relationship developed…the rest is history.

PAC World: Did you have any other interests while in university?

M.A.: I was in the Marching Band for 5 years – the last year as one of the managers. My crowning achievement in marching band was playing a 10-gauge cannon for the 1812 Overture for Homecoming my 5th year.

PAC World: What was your first job?

M.A.: I did work quite regularly for my father – starting at age 10 – and I continued working for him until my co-op years at AEP. No jobs in between.

PAC World: Is there any event from this time that you would never forget?

M.A.: I designed the wiring and implemented it in my first house when I was a Junior in High School.

PAC World: How did you become a system protection and control engineer?

M.A: When I met Dr. Phadke, he was involved in an R&D project to implement Protection and Control in a Digital Computer. Dr. Phadke asked me if I would like to work for him in building a model power system and interfacing it to a computer A/D – I answered yes and never looked back.

PAC World: Seven years after getting your Master of Engineering EE degree from Cornell you got a Master of Science EE from the Polytechnic Institute of NY. What happened?

M.A.: I was working with 2 PhDs (Phadke and Thorp) and a mathematician with an MS (Ted Hlibka) and my work was migrating more towards the digital realm and the University was one subway stop away so going forward, it was a natural.

PAC World: What is the most challenging project that you worked on at AEP?

M.A.: There were several. In 1979, AEP performed Single Phase Staged Fault tests on the Kammer – Marysville line. The challenge was extinguishing the secondary arc when a single pole trip was issued. We brought a Digital Relay to Kammer and interfaced it to the line and captured all the tests. I learned how to interface to 765kV CTs and PTs – without taking a line outage. Installing the world’s first PMU in Marysville; Demonstrating the efficacy of Variable Spot Pricing on the AEP system (500 homes); Analyzing several “unique” operations on the AEP system. The last project showed the opportunity to use Synchrophasors to see a generator starting to accelerate towards instability and subsequently, the opportunity to keep the unit from going unstable through remedial action. Part of my job was the tracking of Optical V/I sensors. Things got exciting in 1989 (ABB and Square D had prototypes) but unfortunately, the market never developed.

PAC World: What was the most satisfying project you worked on?

M.A: I was the designer of GE’s Current Differential Relay (L90). Many unique concepts were implemented (e.g., fractional window phasor estimation, dynamic operational slope based on the quality of the input signal). I did the design for GE’s first High-Power Digital Playback system. It took COMTRADE files; converted the data to analog signals and fed the analog signals into High Power amplifiers that could output up to 280Vpk and 200Apk.

PAC World: After working for a utility for 15 years you started working for a manufacturer. Why?

M.A.: There was a tight linkage between AEP and GE – dating back to the 1930’s so I had much contact with GE Protection and Control over my AEP career. I did demonstrate a ¼ cycle digital relay that I had developed at AEP to GE and GE was impressed. GE made me an offer I couldn’t refuse….no regrets 30 years later….

PAC World: How did your career at GE develop to bring you to the position of Director – Advanced Technologies – GE Digital Energy?

M.A: My primary role throughout my GE career was identification and development of Advanced Technology. GE gave me the title that demonstrated such.

PAC World: What is the most challenging project that you worked on at GE?

M.A.: GE took on a project using a TASNET protocol translation system. After the installation, there were 200 exceptions… we worked through them one at a time.

PAC World: What was the most satisfying project you worked on?

M.A.: Clearly, the development of GE Current Differential relay.

PAC World: You have been part of the transition from electromechanical and solid-state relays to microprocessor-based protection IEDs and then to digital substations. Do you see a difference between these two transitions?

M.A.: I did not look at the digitization of the substation as two different transitions as many of the elements of the Digital Substation were envisioned in the early days. During my involvement in the Digital Revolution (starting at AEP), we would have Strategy Sessions that looked at what the future would bring. I have an AEP diagram from 1978 that shows the concept of a Process Bus in a substation where the data from one A/D converter would be shared with multiple relays. Additionally, I worked on a communication protocol at AEP that would provide remote access to substation data. Although George Rockefeller and team implemented the first digital relay, the Phadke team had the first COMMUINICATING relay that would connect with an IBM 370 Mainframe in NYC through the IBM Remote Job Entry protocol to upload and print captured Oscillography records from an IBM System 7 minicomputer (documented in an early Phadke, Ibrahim, and Hlibka paper).

PAC World: You have been actively involved in the development of the Smart Grid. How did that happen?

M.A: In 1989, AEP launched a demonstration project on the elasticity of electricity based on Variable Spot Pricing. This project involved communicating with hundreds of meters in 3 different regions of the AEP system. The primary result was that there is elasticity in the use of electricity as energy prices were varied but the second outcome was that Direct Load Control (DLC) was possible through the established communication system. I have revised the terminology and have coined the phrase “Surgical Load Shed.” The Smart Grid is getting the communications right.

In 1992, EPRI launched RFP 3599 to develop an architecture for the Digital Substation. I put together the GE team that bid and won the RFP. This work became the foundation for UCA. Side note: during the course of the project, GE and EPRI separated and other were brought in to finish the work, which, as is known, morphed into IEC 61850. Also, to be noted, the GE response to the RFP 3599 included the proposal of using Object Models for identifying data in the Utility Enterprise. I had recently learned about Object Modeling from my friend, Dr. William Premerlani, who was one of the authors of an early book on Object Modeling.

I also led the effort in GE to bid and win the EPRI RFP for the development of the Smart Grid Architecture – known as IntelliGrid. Much of the results from this architecture development have been adopted by NIST in what is now known as the “NIST Framework and Roadmap for

Smart Grid Interoperability Standards.” It is to be noted that IEC 61850 was the primary communication protocol identified to address all communication scenarios.

PAC World: For many years you have been involved with IEEE and CIGRE. When and why did you join?

M.A.: I joined IEEE in College – mostly because it was the thing to do. I did get involved with IEEE as the Winter Meetings were usually held in NYC and AEP had much involvement.

Regarding CIGRE, Arun Phadke had been involved in CIGRE in a number of capacities, so I was aware of the organization and I was aware that Philip Sporn, AEP CEO and protection engineer, was very involved in CIGRE. I had written a paper for CIGRE publication back in the early 1990’s. When the opportunity came to represent the US at CIGRE, I was ready, willing, and able (and supported by GE) to take up the cause.

PAC World: How important do you think is the role of IEEE and CIGRE for your development as a professional?

M.A.: Both organizations were important for different reasons. IEEE allowed me to get involved with aiding (sometimes setting) of consensus in the development of standards for the power system industry. In one such case, when the first COMTRADE standard was being balloted (1991), I voted negative as the document did not provide for a Binary Data File option for the standard. The chairman, Dr. Phadke, gave me the opportunity to create one – which was part of the 1991 Standard.

CIGRE allowed me to create international connections which allowed me to better understand International requirements for protection and control.

PAC World: Today we are part of the transition from hard wired protection and control systems to IEC 61850 communications based fully digital substations. What is your opinion about it, the benefits and challenges?

M.A.: As noted, I was one of the EARLY adopters of digital technology in the substation. Digital technology provides much more flexibility in the implementation of a Protection and Control system and the opportunity for cost savings – and Digital Technology has been adopted by the Electron Industry. Not all related technologies have been adopted. One of my roles at AEP was the tracking of Optical measurement technology. ABB and Square-D had implementation in 1989. Unfortunately, adoption has been slow to non-existent. Moreover, many of the early providers are no longer in business. Process Bus should have provided an impetus to adoption…. But it never happened.

PAC World: The electric power grid today is very different from the power grid of the twentieth century. What do you think about the impact of inverter based distributed energy resources on protection and control systems?

M.A.: To start, there is an un-asked question as to how the grid will perform when MOST power is inverter based? There has been much speculation and modeling of such systems. It appears that, due to the speed of response of inverter systems, the grid will survive. With regard to protection, new protection schemes will be needed as traditional current-only schemes will not have the selectivity to isolate only the faulted elements. This is where a communication-based Smart Grid infrastructure will make a difference as it will enable new protection schemes to evolve.

PAC World: What do you believe is the best way to share your knowledge and experience with the new generation of protection engineers?

M.A.: Relating to the earlier question on the effect of IEEE and CIGRE (and IEC) on my career, education through these organization is needed. Additionally, I have presented a course on UCA/IEC 61850 for Continuing Education at University of Wisconsin since 1997 as well as at numerous venues (e.g., PACWorld) throughout the world. I promoted hands-on learning where attending students learned how to build an Ethernet network in the classroom and how to capture and analyze WireShark traces of GOOSE and Client/Server messages.

PAC World: What do you think is most important for a protection engineer’s development?

M.A.: An interest in power systems; a desire to learn, and a mentor.

PAC World: What do you consider the biggest challenge in your professional career?

M.A.: Watching executives make decisions on a purely financial basis and not being able to see the bigger picture.

PAC World: What do you consider your biggest professional accomplishment?

M.A.: Development of the GE L90 Current differential. Dr. William Premerlani was a PhD from GE’s Research Lab who came to live in the Malvern, PA area for a summer. We worked late into the night for 4 months on the development of the mathematics for the relay. A 90-page patent was filed on the various elements of the algorithm that were unique in the product. We introduced the term “Phaselet” which was a fractional phasor that could be developed with only 2 samples of data (based on the work of Phadke and Thorp).

PAC World: You have received many awards and recognitions. Which is the one that is the most important to you?

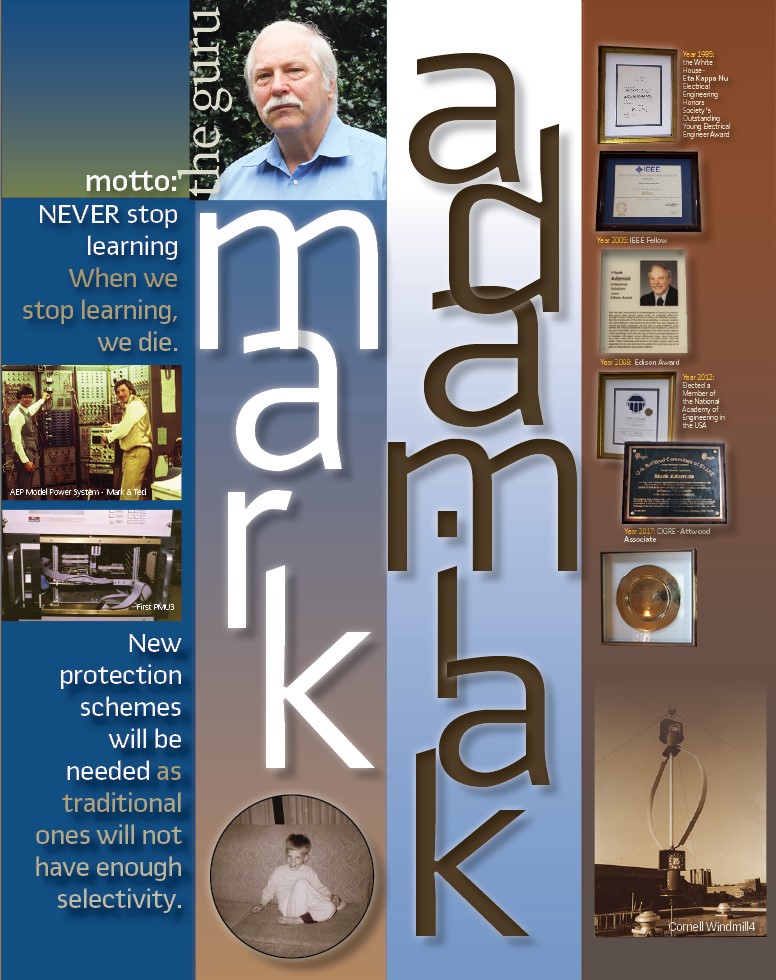

M.A.: I feel most honored by my election into the National Academy of Engineering, but I do relish my letter from Ronald Reagan for my HKN Outstanding Young Electrical Engineer award.

PAC World: What do you think we need to do to attract more young people to our industry?

M.A.: This is an interesting question as it was asked back in 1979 where I convened an IEEE panel at the Winter Meeting in NYC on this topic. The answers from 1979 ring true today which is to make the work exciting and interesting.

The Digitization of the Electron Industry (larger than just utilities) integrates communications, networking, cyber security, circuit design, database design, User Interface Design, and the integration of new technologies such as Optical Sensing, Thermal Imaging, Drone Surveillance, and basic power engineering. Presenting these topics as needed in the power industry should be a major drawing card.

PAC World: What is the advice that you would give when you are in front of an audience of young people?

M.A.: Always approach whatever you do with enthusiasm.

PAC World: What do you think is your most important personal achievement?

M.A.: Having a wife of 38 years; 3 children; 4 grandchildren; and friends around the world.

PAC World: You have traveled to many countries. Do you have a favorite place to visit?

M.A.: I have visited 47 countries in my career. My two most favorite places are Rio de Janeiro and Switzerland.

PAC World: Do you have a hobby or something that you like to do when you are not working?

M.A.: I do play the piano – good enough to get a free meal or a drink. Once when dining at a restaurant at the Jackson Hole ski run, I started playing the piano in the restaurant. The chef loved the music and sent a tray of stuffed mushrooms to our table. I do enjoy skiing and I have built a drone – using a controller designed and programmed by a good friend of mine. I could probably take on most comers in Ping Pong.

PAC World: You have been married for 38 years. What is the secret?

M.A.: Love as a Commitment.

PAC World: How do you mix your professional and your personal life?

M.A.: I have traveled extensively and my wife, Susan, has had to fill in the gaps for when I was gone – which she did quite a number of times and quite successfully. She did get to travel with me to unique places such as Berlin, China, and Milwaukee…

PAC World: You are still working in different roles. Do you ever consider retiring?

M.A.: I have hung out my Consulting shingle and a number of opportunities have come my way. At some point, I do envision completely retiring – but not just yet. Most recently, I have become involved with a company that has developed the communication security defined in the IEC 61850 standard. I am looking forward to being able to implement such in real-life applications.

PAC World: What is your favorite music?

M.A.: I have an eclectic taste in music. I do tend to gravitate to 1960’s and 1970’s music and also have a sizable classical music library but will adopt any song that catches my fancy.

PAC World: What is your favorite form of entertainment?

M.A.: Playing piano is a form of entertainment and relaxation. I have a 4-wheeler which I love to drive around the Catskill Mountains. I am an avid Pinocle player…. and I love air hockey – which became popular during my college years.

PAC World: Do you have any favorite food?

M.A.: Potato Pancakes.

PAC World: Do you have a motto?

M.A.: NEVER stop learning. When we stop learning, we die.

Biography:

Mark Adamiak is an independent consultant for the electric power industry. Mark started his career in the utility business with American Electric Power (AEP) and in mid-career, joined General Electric where his activities have ranged from advanced development, product planning, application engineering, and system integration in the Protection and Control industry. Mr. Adamiak is an original member of the IEC61850 WG, a Life Fellow of the IEEE, a registered Professional Engineer in the State of Ohio and a GE Edison award winner. Mark was the Principal Investigator for the EPRI IntelliGrid project to develop a reference architecture for the Smart Grid. In 2012, Mr. Adamiak was elected to the US National Academy of Engineering.