by Rene Troost and Sjors van der Heijden, Stedin Netbeheer B.V., The Netherlands

Once upon a time grids were able to work without any digitalization. Autonomous functions were achieved through mechanical devices, and operators resided in company-owned houses adjacent to the primary substations. With the advent of electronics in the seventies, and the retirement or relocation of the last operator to a central control room in the early nineties, the distribution grid gradually began to receive attention for digitalization. However, it took several decades before significant progress was made in this area. Currently, the distribution grid is the most dynamic part. This is the result of large-scale Photovoltaics, Electric Vehicles and Heat Pumps.

As grid operator this gives challenges to make our needed investments predictable, to manage/avoid congestion and find blind spots where the grid load is different than assumed. Besides the needed grid visibility digitalization supports the control of public lighting, FLISR improvement and asset performance monitoring.

Stedin is a grid operator in the Netherlands with around 2,4 million customers, mainly in urban (i.e. Rotterdam, the Hague & Utrecht) and industrial areas (The ports of Rotterdam and Zeeland). The grid exists of ~20.000 secondary substations. These substations basically consist of a medium voltage (MV) Ring Main Unit (RMU) a MV/LV transformer and a low voltage (LV)-panel to connect households and small business customers. Additional to the Stedin-owned secondary substations, there are thousands of customer stations with their RMUs in Stedin’s MV-rings.

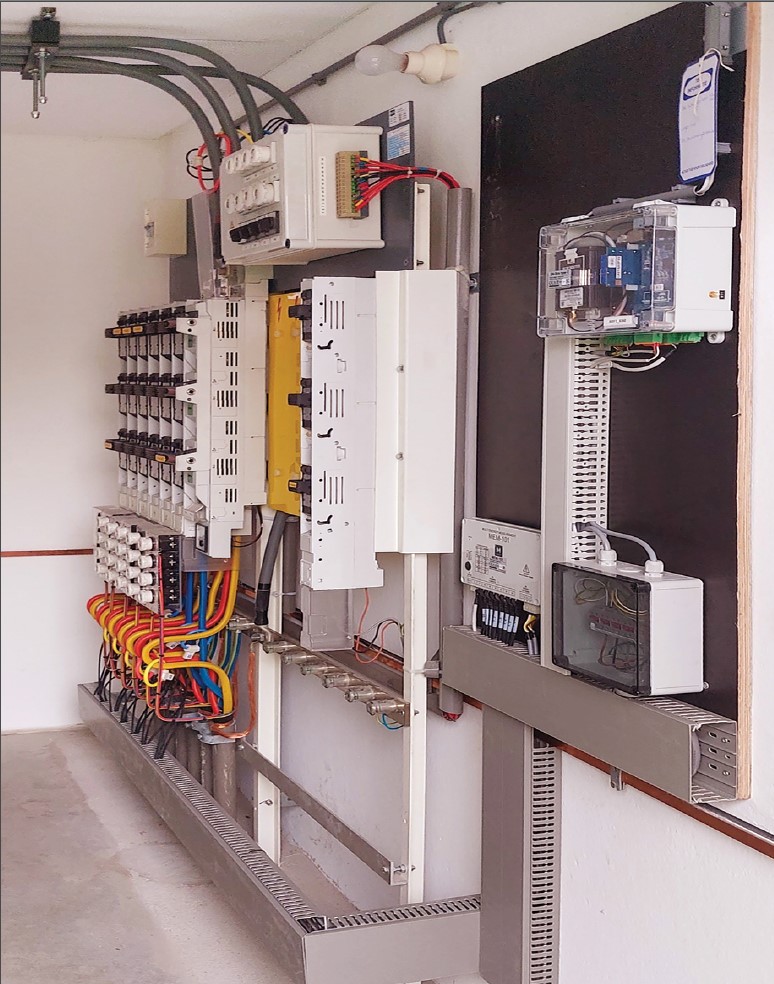

Around the year 2014, Stedin started several programs to add digitalization to the distribution grid. Remote controlled RMUs and centrally reported fault passage indicators (FPI) were installed mainly to reduce Customer minute lost (CML). The aim to install Smart Grid Terminals (SGTs) was monitoring loads, Power Quality and controlling public lighting. Latter as an alternative for the outdated ripple control systems. By the year 2023, approximately 20% of the grid has been equipped with this particular type of equipment. (Figure 1).

Stedin has made the decision to develop a single digitalization platform for all their approximately 20,000 secondary substations. This platform will incorporate all the functionality of previous equipment while also addressing present and future requirements.

Gather and Structure Needs

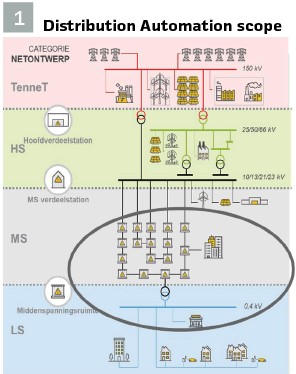

The initial step involved arranging interviews and brainstorming sessions with pertinent stakeholders. This led to the creation of a list containing use cases where the automation of secondary substations can be beneficial. Based on these use cases, functional and component requirements were derived. (Figure 2).

Subsequently, decisions were made regarding which requirements must or should be fulfilled, taking into account factors such as maturity, costs, and benefits. The specification for the EU tender process was then developed using a system engineering methodology and a requirement management tool. Within this requirement management tool, requirements are interconnected, for instance, linking component requirement x to user requirement y.

Tendering

While securing a good price is certainly in Stedin’s interest, the primary focus was finding the optimal solution for the specific requirements. Initially, numerous potential suppliers, including both established companies in the sector and newcomers, were invited for open dialogues based on the initial version of the functional requirements. This initial phase resulted in the first iteration of the requirements and specifications.

After selecting a subset of suppliers, a conceptual version of the specifications shared to assess the feasibility of the request and determine which requirements had a significant impact on product development. Using this feedback, a second iteration of the specifications conducted. Based on this refined specification, the selected suppliers were asked to submit their offers.

To evaluate the offers, a fictional discount was applied, which could be obtained by scoring well on qualitative awarding criteria. These criteria were based on factors such as ease of software changes, efficient data utilization, ease of commissioning, user-friendly tools, required maintenance, and installation and disassembly times. For the latter criterion, three suppliers were required to provide demo equipment that was installed and disassembled by Stedin technicians. The faster and smoother the process, the higher the score, and consequently, the lower the total weighted price.

Data Exchange

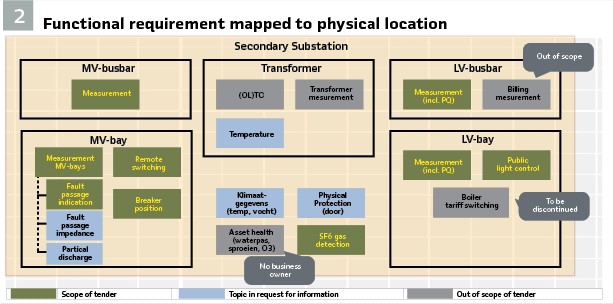

Traditionally, Distribution Automation (DA) Remote Terminal Units (RTUs) communicate over mobile communication using IEC-60870-5-104 with SCADA systems. The data is used for real-time applications. Non-real-time data applications in the office uses the historian database. For the DA RTUs, most of the sensor data is only being used in the non-real-time domain. From that point of view, it makes sense to separate data flows meant for, respectively the control room (real-time) and office (non-real-time) use. Another aspect is the huge number of devices and their datapoints that have to be handled. Because Stedin decided to measure all Low Voltage (LV) feeders of 0.4kV, an average of 500 data point will be sent by the RTU. The headend has a role in the architecture to route these data streams. This creates a loosely-coupled design with a clear demarcation point and a good routing of data. (Figure 3).

The starting point was to use the IEC TC57 reference architecture, where IEC 61850 is being considered as the leading standard within this domain. The main idea is to reduce the amount of data(model)translations to a minimum. However, this principle was not always easy to reach.

To have a lean and stable connection over the Wide Area Network, the idea was to use XMPP (Extensible Messaging and Presence Protocol), which implementation is described IEC 61850-8-2 standard. That protocol was implemented in the standard for this kind of use cases. Unfortunately, the standard was just published a few years before the tender which resulted in extremely little experience and references. Up to now, the references are limited.

The first data stream is into the OT landscape. In order to establish seamless interaction with the Control Room’s SCADA/DMS, the utilization of IEC 61850 is preferred. This approach helps avoid the need for data translation, mapping, and significantly simplifies SCADA engineering through the use of Substation Configuration Language (SCL). Despite being a standard that has been available for approximately two decades, the level of support for IEC 61850 among major SCADA vendors is notably limited. This can be attributed to the fact that user demand for IEC 61850 has been relatively low.

While this limitation may be a point of consideration when acquiring a new SCADA system, it is not a sufficient reason to switch from one vendor to another. Consequently, Stedin is compelled to adopt a complex transitional architecture, beginning with IEC 60870-5-104 and later on transitioning to IEC 61850. This approach allows for the integration of the desired functionality while navigating the limitations imposed by vendor support.

The second data stream is into the IT landscape. To handle all this data, Stedin decided to create a Kafka platform. For this topic the main question was: how to model the IEC 61850 data within an IoT platform, i.e. how to deal with other protocols which are not into the IEC 61850 standard? The first idea was to communicate using the standard IEC 61850 MMS protocol to the streaming platform. This wasn’t impossible, but not a standard Kafka implementation. Besides that, the data would be communicated differently further in the data chain after the streaming platform. The only requirement is that the data model remains in place after communication by another standard. With this in mind it was decided to use the Apache Kafka standard communication protocol between the headend and the streaming platform.

How to Organize a Full-scale Roll-out?

A roll-out program of this size and nature is something different for grid operators. It needs both knowledge and experience from Substation Automation and Metering domain. It is hard to realize the roll-out like a High Voltage Substation Automation System (SAS) project, due to the high amount of repetition and needed efficiency. On the other hand, a Smart Meter roll-out is also not fully comparable due to its lack of modularity, needed certificates and substation configuration diversity.

Performing a roll-out without a highly automated process leads to a situation where too many (SCADA) engineers are needed. All the datapoints needs to be added manually and a relatively highly (IT) educated field staff is needed to configure and commission the (de)central systems. Additionally, there is a significant risk of errors with manual configuration. For this reason, it has been decided to automate repeating actions as much as possible. Another principle is that field staff with limited IT-knowledge should be able to install and commission the decentral systems without special notebooks with configuration tooling.

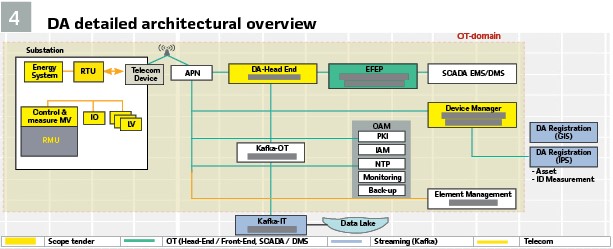

The scheme in Figure 4 is used in the tender and shows the system landscape including which parts were scope of the tender.

The idea is that the RTU system arrives in the field in a ‘vanilla’ configuration, which means it is configured with standard firmware and software. After booting the system it will contact the central server. The field technician provides the combination of substation ID, serial number of the RTU and local situation (e.g. number of sensors). This gives the central system the required data to load the appropriate configuration in the RTU system and to register it. After commissioning all changes that don’t need physical interaction with the decentral system will be managed remotely, for example the configuration of trigger values of the Fault Passage Indicator (FPI).

Because the sensor data is based on the standard data model, there is no need to translate or map it when used in other applications.

Regarding the physical installation, everything is labelled and designed as plug and play. For example, the LV Rogowski type CTs are colored, flexible and with a click-system to attach around the conductors. (Figure 5).

Current State

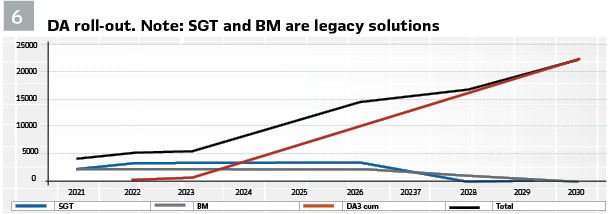

In the spring of 2023, a ‘general rehearsal’ is performed by installing the first 50 systems in the field. The purpose is to experience installation in different types of substations, to check processes and validate use cases. After this, an iteration review is done to improve the implementation process. In the end of 2023, the full-scale rollout based on the production environment will grow towards approximately 3,000 systems a year. In 7.5 years all relevant secondary substations (>80%) will be equipped with this system. The order of roll-out is based on prioritizing the areas with the highest demand for sensor data (e.g. congestion and power quality issues).

Another significant aspect to consider is the presence of legacy equipment reliant on 2G communication. This particular group of devices needs to be replaced with the new DA generation prior to the anticipated shutdown of 2G services by the telecommunication providers. Taking proactive measures to upgrade this equipment is essential to ensure uninterrupted communication and operational efficiency. (Figure 6).

The significance of achieving a rapid roll-out is evident by the fact that it is a key performance indicator (KPI) at the board level. This underscores the importance of the Distribution Automation (DA) roll-out, as it is included in Stedin’s annual report to stakeholders. Timeliness is critical in this regard. It is essential to prioritize the establishment of grid observability before making investments to reinforce the grid. By doing so, the short-term benefits of sensor data can be maximized. For instance, utilizing DA sensor data to measure the available capacity of an existing distribution transformer enables the implementation of a specific approach to electric vehicle (EV) smart charging. This approach optimizes the utilization of resources based on real-time information, ensuring efficient management of the grid.

Future Developments

The roll-out process has just commenced, but there is no time to relax. The evolving environment and advancing technology will continuously pose new challenges and requirements. These factors hold relevance for both current and future contracts. To effectively address and explore these developments, Stedin has devised a PAC (Protection, Automation and Control) roadmap.

The PAC roadmap incorporates both an outside-in and an inside-out approach to comprehensively identify and assess potential technological opportunities. The inside-out approach begins by identifying the organization’s needs and subsequently seeking out and offering suitable solutions. On the other hand, the outside-in approach investigates developments in products and services to generate a desire for addressing organizational challenges.

Within the domain of Distribution Automation (DA), several technological opportunities hold relevance. These include edge computing, open container (docker) platforms, and new pricing models. These examples exemplify potential avenues for enhancing DA capabilities and adapting to emerging trends in the field.

Conclusions

The ongoing roll-out program has yielded some noteworthy insights. Firstly, it has become evident that achieving a significant scale of grid digitalization necessitates the automation of repetitive tasks and the ability to deploy devices with technicians possessing limited IT skills. Unlike primary substations, most secondary substations lend themselves well to highly standardized solutions. Therefore, a small number of standardized configurations can cater to over 95% of the locations.

The second observation is that this automated configuration and registration process has a significant impact on the existing IT/OT (Information Technology/Operational Technology) landscape. It affects multiple applications and departments within the organization. Additionally, the capabilities of existing applications, such as SCADA, may pose limitations in facilitating sophisticated data exchange.

While IEC 61850 is widely adopted within the Substation Automation domain, it has yet to gain widespread recognition as the leading standard among software vendors for central IT/OT applications. This necessitates the implementation of complex transition architectures to bridge the gap between the current state and the desired target architecture. Completing this type of roll-out requires a significant amount of time. However, it is crucial to prioritize the roll-out locations carefully, considering the exponential increase in congestion within the medium voltage (MV) and low voltage (LV) grids. It is important to note that the installation of sensors alone does not immediately result in useful data. Generating a comprehensive yearly profile requires at least one year of measurement data. Thus, initiating the roll-out in a timely manner becomes imperative.

In the past, MV and LV grids were designed based on standard rules of thumb and common profiles. However, in today’s dynamic landscape, both the MV and LV grids require full grid observability to effectively manage their complexities. This shift underscores the need to establish comprehensive monitoring and observability systems to adapt to the evolving grid dynamics.

Stedin made the strategic decision to collaborate closely with vendors throughout the tender process. This involved conducting market consultations and engaging in iterative discussions to refine the requirements. However, despite these efforts, it became apparent during the Request for Proposal phase that not all requirements were fully aligned between Stedin’s account managers and the technical experts within the vendor organizations. As a result, this misalignment caused delays in the process.

Stedin acknowledges its role as a frontrunner in the tender process, recognizing the need to navigate the challenges and complexities that arise during the procurement phase. By addressing the misalignment and working towards a consensus on the requirements, Stedin aims to overcome these hurdles and ensure a successful outcome for the project.

The final observation pertains to the preceding paragraph. When implementing a grid digitalization program of this magnitude, it is essential to establish a concept that can be maintained effectively for a minimum of 15 years. To achieve this, consideration must be given to the latest developments and standards in the industry. However, in practice, it is not always possible to find the latest standards readily available in commercial-off-the-shelf products. This creates a discrepancy between the available state-of-the-art technology and the most recent standards.

Addressing this gap becomes a challenge that necessitates finding suitable solutions or alternative approaches to bridge the divergence between technology advancements and the incorporation of the latest standards.

Biographies:

Rene Troost graduated as an Electrical Engineer and started his career in Telecommunications. In 2014, Troost joined Stedin, the DSO for the South-West area of The Netherlands, including the Port of Rotterdam. Troost is currently responsible for substation automation policy in Stedin. He chairs the Dutch technical working group designing a DSO/TSO-DER interface, is an active member of the Dutch Committee of the IEC TC57 (NEC57) and the Technical Committee TC57 WG10 that deals with power system intelligent electronic devices (IEDs), communication and associated data models and chairs the Dutch CIGRE B5 study committee.

Sjors van der Heijdenis grid strategist with a focus on automation in the distribution grid at the Asset Management department of the Dutch DSO Stedin. His responsibilities are policy regarding network services, operational technology/IoT, analytics and grid control. He has over 10 years’ experience on infrastructure automation. Mainly in the energy sector but also in water systems (canal locks, bridges and flood barriers). Which results in extensive insight and experience in system -engineering, -architecture, sourcing, standardization, asset management and (technology) roadmaps.