by Eric Udren and Rich Hunt, Quanta Technology, USA

What is Sustainable Design?

A sustainable design approach is becoming critical to survival as PAC systems and equipment move towards communications-based architectures and IT-like modularity of functions with rapid obsolescence of underlying technology platforms. A utility that carries on with legacy design and installation approaches tends to adapt new products individually at each substation until the diversity of equipment types, schemes, wiring and installation techniques, firmware versions, and performance evidence are difficult to track and manage. Maintaining protection systems becomes a business of triage of the most challenging failures and misoperations with a great deal of customized manual work.

This article presents a checklist of methods, tools, and management strategies that can sustain the PAC fleet and its design in these times of rapid change and obsolescence. The authors have seen how many utilities have adapted and are already positioned to check off many items in the list. Adapting legacy practices to sustainable ones requires acceptance and enthusiastic vision by multiple stakeholder departments of the utility, along with investment of financial and human resources by the utility business management.

Meeting the Sustainability Demands of Today’s PAC Business: The introduction of microprocessor-based multifunctional relays with programmable logic, followed by system integration of relays based on data communications, brought a combination of new functional arrangements and rapid product obsolescence that upset the stability and usability of many old systems and procedures. Utilities have been learning to manage fleets of relays with thousands of configuration settings, vendor-specific interaction of functions, and constantly changing firmware versions. Relay manufacturers supply products that change substantially every few years, driven by their own component vendor change cycles as well as competitive marketplace demands.

This is combined with a rapid increase in regulatory requirements that impact PAC design, setting, maintenance; cybersecurity requirements for communications integration; as well as operating restrictions for the power system that make outages harder to schedule.

Helpfully, the evolution of P&C design and operating demands has taken place in a business world that also brings new tools for management in times of rapid change. By applying these tools and methods and recapturing the underlying core principles of stabilizing designs at a more rapid evolutionary pace, utility engineering, operation, maintenance, and asset management teams can achieve the reality of being in full control of the domains for which they are responsible, as well as the business benefits that result.

Role of IEC 61850 integration: IEC 61850 adoption is directly supportive of a sustainable PAC design and management regimen – it was designed as it is for this reason and is recommended in this article. However, it is not in itself the whole solution to sustainability. Utilities can implement sustainable design without IEC 61850 services. These utilities face more work with manual mapping of data points or wiring connections; but may be comfortable with that path as they evolve the capabilities and skillsets needed for IEC 61850 and IT-like Ethernet based systems.

The Elements of Sustainable PAC Design

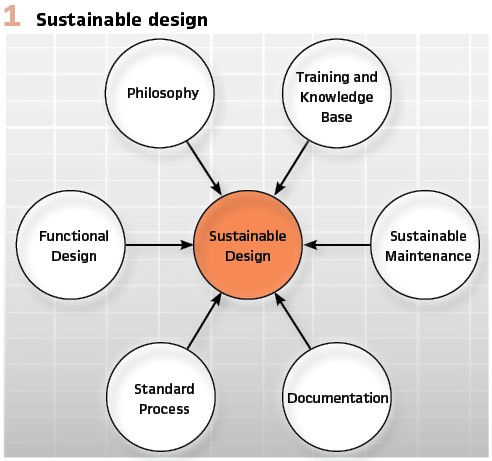

We summarize here the elements of a sustainable program for PAC design and management. Each is explained in a subsequent section. (Figure 1).

1. Philosophy – living, updated principles that form foundation for each utility’s total approach to PAC design and management – and not limited to just protective relaying approaches

2. Standard functional designs that are managed and kept stable for entire revision cycles

a. Includes panel, installation, and maintenance designs with sustainable panel and user facility focus

3. Process for managing and updating the design standard in cycles of several years

a. Workflow management systems or processes that confirm routine updating for each of the above elements

4. Standard documentation packages

a. Layers include specifics of IEC 61850 design configurations and architectures if used, and other architectural documentation in any case

5. Sustainable maintenance practices

6. Training programs and knowledge base

Philosophy – the Foundation for Sustainable Standard Design

The goal of philosophy documentation is to set down any durable principles impacting PAC design and application which transcend a particular project need and will remain applicable for the foreseeable future. The philosophy is updated as practices evolve over time. The philosophy is then available to guide development of design standards and of project documents descending from those standards. They also educate team members and serve as a platform of agreed and shared technical and practical specifics.

All of the details in a sustainable standard design should descend from and be aligned with a set of principles and requirements embodied in this broad concept of philosophy. A team of engineers developing a new standard design or updating existing standards can use the philosophy to achieve a consistent evolution of approach at the most effective point in the design process that will make the transition easier for project engineers, construction personnel, field maintenance personnel, and system operators.

They will save time spent in unnecessary revisiting of basic approaches or evaluating products that don’t fit these well-established approaches that have been vetted by all stakeholders. Many utilities have documented their protection philosophies and typically record experience-based design requirements for:

- Protection applications and settings as a function of type of protection zone, configuration, voltage level, criticality.

- Use of special protection functions as provided by product manufacturers or with custom logic.

- Redundancy and isolation requirements.

- Teleprotection applications and selections.

Additional topics for which philosophy documents can help a team of engineers with varying levels of experience create consistent standard designs include:

- Panel configurations by protection zone or function for easy future updating

- Wiring and fiber configurations and terminations, also for easy replacement and updating

- Grounding and field wiring design

- Compliance strategy for each regulatory standard

- Maintenance strategy with panel and installation facilities to enable it

- Local and remote presentation of situational and event information

- Naming and identification approach for substations, lines, equipment, panels, wiring and fibers, and primary equipment

- Approach to the development and maintenance of design standards as explained below – separate from the resulting design standards themselves

- Approach to project handling and workflow management, including maintenance of the philosophy documentation itself

The creation and periodic maintenance of philosophy documents is a significant effort, but engineers and managers who embrace and document specific philosophy topics become subject matter experts who can then effectively develop and maintain the elements of specific design standards. New PAC engineering team members are better positioned to learn from the philosophy and standards documentation and to succeed with specific projects assigned to them.

Evolutionary drivers like new regulatory requirements, misoperation experiences, adoption of special situational grid operating practices, penetration of DER, or changes in skills and tools of field personnel are best accommodated by updating the specific affected topics of philosophy and design standards, even if they are first encountered in specific installation projects. Future projects can benefit from the evolution without reworking successive project designs.

Standard Designs that are Replicated Across the System

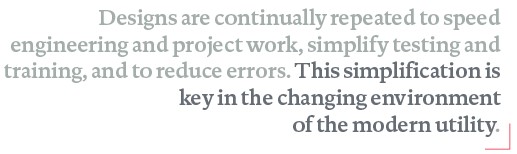

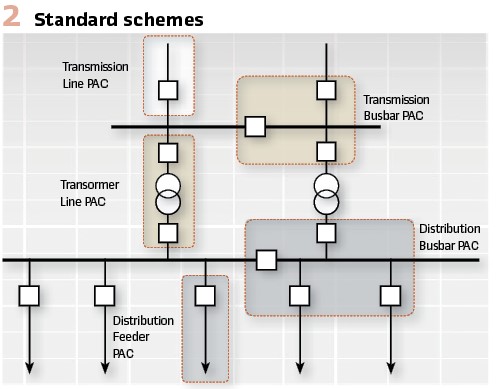

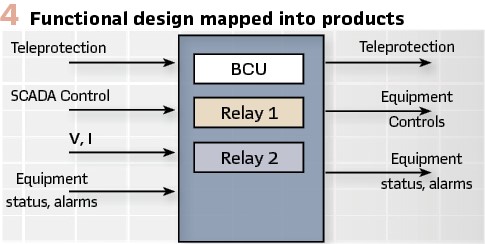

The selected philosophy drives a functional design that is the basic specification for protection and control for zone of the substation. (Figure 2). The transmission line terminal shown in the block diagram of Figure 3 is one such design, describing the functionality for a specific zone; the required number and type of current, voltage, control, and status inputs; and the required number and type of equipment control and equipment status outputs. The design includes the intent of any control logic, teleprotection requirements, SCADA reporting and control details, device and equipment naming and naming conventions, and operator interfaces. This functional design is fixed as a standard and will only be changed through a formal revision process.

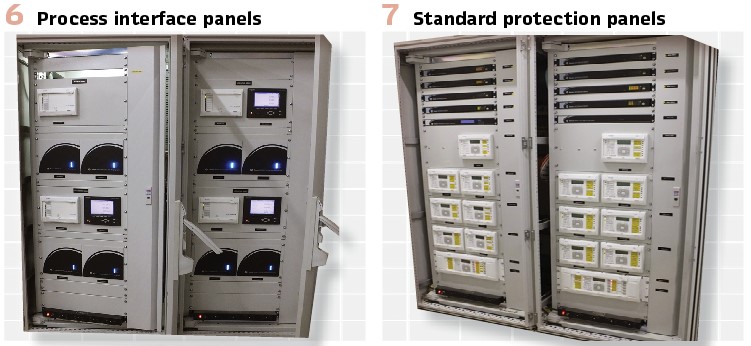

The actual design standard for the zone maps functional requirements into actual products and installation details as in Figure 4. The specific products, internal logic, device configuration templates, panel design, and physical wiring are part of the standard design. The result of this is a standard design package that includes the design, design documentation, and calculation sheets needed to apply the protection philosophy to the devices, with the goal of minimizing the need for hand-crafting solutions for specific projects.

A good functional design standard does provide some coded options to account for practical details such differing types of teleprotection schemes, long- versus short-line applications, or bus configurations. A benefit to this approach is the ability to update the standard design due to changes in the availability or desirability of component devices, or to replace field wiring with IEC 61850 communications.

Designing equipment panels using the modular approach suggested by Figure 3 and Figure 4 makes it possible to perform live replacement of redundant systems, using safe replacement procedures without requiring an outage. It is obvious that this standard design provides great flexibility in installation, especially in refurbishment projects in existing substations. Projects can be performed one panel at a time, or a whole building replaced at once.

The Standards Process

The goal in creating design standards is to develop all the materials that can help a protection engineer deliver a design package for a project with these features:

- Highest consistency among installations – construction, maintenance, and operating personnel understand from experience how to deal with it

- Lowest risk of human errors by the design engineer, project construction and commissioning personnel, and test technicians

- Fastest execution and lowest cost for successive projects

- Accurate and easy access to well-organized database of design documents and data

Elements of a design standard process:

1. Fixed standard design with periodic revision cycle – The standard design is kept in place with only essential modifications for a fixed period, typically 3 to 5 years. This results in a generation of field project installations that are consistent and familiar to maintenance and operating personnel

2. Separate parallel next-generation standard development track – As the current design is deployed over years, a parallel effort evolves and completes the next-generation design standard. This includes evaluation and testing of new products, technologies, and schemes including laboratory testing, along with training on the new standard

3. Standard development and maintenance laboratory – Panel assemblies capable of implementing commonly used standard functions and zone types in a typical substation standard are permanently set up in a laboratory with space and test equipment for experimentation and validation. The laboratory is used to develop scheme logic and settings with event testing scripts, try new products, validate firmware versions, and vet operating and testing procedures with field personnel, and can be used for operating event analysis.

4. Configuration management systems – design documents, including setting or configuration files of relays and IEDs that must be quickly and accurately accessed for maintenance, are to be kept in a managed system with versions of every item, status versus stages of development, and tracking of delays or of items overdue for attention. With the thousands of settings, one error can disable the installation – rigid control and reliable access of exactly the intended configuration file or data is critical to power system reliability.

5. Workflow management systems – All the activities in PAC development for a project, from inception to in-service status, are managed with team processes. Tracking is visible on a dashboard. All work items are tracked by unique version and project identification.

Notably, development of the next-generation standards, and maintenance of philosophy documentation, are workflows that should be managed in this way so that the status is always known.

Documentation of Standard Designs

Sustainable repeatable design carries through to the documentation. Every standard design has a documentation package with identical content. This documentation is a complete description of the standard, including protection calculations, device configurations, and physical design and layout. The package includes:

- Description of the standard. What the functions are, the inputs and outputs, devices, naming conventions, logic, and interfaces to other zones. This includes the model number and firmware version of the IEDs used in the design

- Drawings including panel layouts, AC and DC schematics, and logic diagrams

- Maintenance documentation, including descriptions and drawings showing maintenance and indication facilities, along with test plans and test scripts.

- Communications design, including network architecture and network data flow diagrams. Also covered is polling / reporting data for SCADA and PMU clients. General cybersecurity provisions will be included as well

- Relay and device documentation. This includes protection setting calculations sheets, compliance elements to be checked when performing calculation, and templated configuration files for all devices, along with calculation and configuration tools

This standard documentation package is the basis for project engineering, maintenance activities, and training through consistent documentation delivered in consistent formats for all standard designs.

Sustainable Maintenance Design

Documented and highly standardized sustainable designs, with monitoring and testability built in and proven during the standards development process, create a familiar and convenient interface, along with standard scripts, for routine testing or for diagnosis and correction of malfunctions in PAC installations. This leads to options for sustainable maintenance practices.

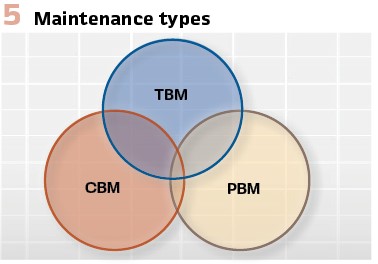

There are multiple maintenance strategies from which to choose, including legacy periodic or time-based maintenance (TBM) testing, whose efficiency can be greatly improved with tuning according to performance-based maintenance (PBM) principles, for example the Annex A PBM program described in the North American NERC reliability standard PRC-005-6. An asset database for all the components in standard PAC designs can categorize specified components according to standard versions, manufacturers, and device types. Failure data can be used to adjust testing intervals up for reliable components and down for troublesome ones. Ultimately, statistical failure data for a population of devices is the key information the utility needs to see the onset of end-of-life and plan for capital replacement, made easier by the standard processes recommended above.

Condition-based Maintenance (CBM) Program

CBM refers to a program in which most of the PAC system elements are able to monitor their own integrity and performance, alarming for failures, and requiring no periodic testing. A full CBM program has no unmonitored gaps in the system and requires no periodic testing. Opportunities for utility TBM operating expense savings are massive. The standard design document set maps the monitoring features and communications path exchanges and shows how every element is monitored.

With full CBM and no routine in-service testing, the asset statistics collected from failures and corrective actions for the range of device types in the standard PAC generation become the basis for determining which components are reaching end of service life and what actions are best to sustain performance. With today’s communicating microprocessor relays, easy replacement of whole zone panels with a new standard design may be the most cost-effective solution when the old unit has served for 10 to 15 years.

The long term goal of sustainable maintenance should be adopting a full CBM program, but TBM can be improved by adopting the PBM concept of statistical history of device performance while both TBM and PBM can be improved by increasing the self-monitoring of devices and PAC systems.” (Figure 5).

Training and Knowledge Base

Sustainable design simplifies training in multiple ways. Training cycles are simpler and more efficient, as training changes from on-the-job experience and general application principles to teaching all stakeholders, such as engineering, field technicians, and operating personnel the specifics of applying their roles based on the standard designs. The standard documentation packages include information, such as philosophy, functional scheme documentation and standard test plans, to form the basis of this training. The standard development laboratory is an important tool in this training.

Another simplification is in institutional knowledge, as the overall protection and control knowledge base is contained in the standards and described in documentation. These documents capture the reason why a functional design is used, details around using the design, how to operate, and how to test. Personnel responsible for these standards become subject matter experts. Field knowledge and experience is captured during standards development, especially in the parallel development of the next standard.

Role of IEC 61850

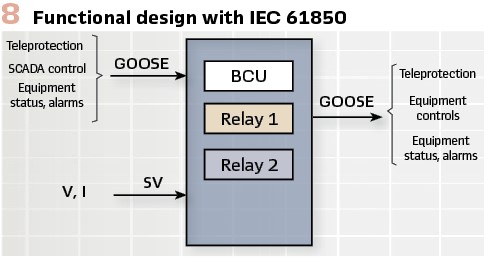

Adopting IEC 61850 is a logical enhancement to sustainable design. IEC 61850 turns every analog interface into digital data, which can be shared throughout the substation. The inputs and outputs for the transmission line terminal simply become the GOOSE and SV messaging of Figure 8. There are obvious design and installation advantages from changing copper wiring to Ethernet fibers, but the gains from IEC 61850 accrue in every step of the standards process.

Some benefits of IEC 61850 in sustainable design include:

- Functional design maps directly into the system specification model of IEC 61850, a virtual description of the data models and data sharing needed for this design

- Standard designs work from the system specification model by adding the IEC 61850 capabilities descriptions of specific devices, and specifying all the data models, data sets, and messaging to share data with other modules

- Standard designs are easily lab tested for performance and are accurately duplicated for every project

- Project engineering uses standard tools to finalize these standard configurations by simply updating naming and addressing, eliminating manual point mapping

- IEC 61850 is self-documented in XML files that become part of a standard documentation package

- Live device testing using safe procedures is supported through virtual isolation and simulation of data

- IEC 61850 designs support full CBM programs as they are assembled from self-monitoring IEDs exchanging critical data by heartbeat messaging. Messaging failure is alarmed to assist in troubleshooting issues

IEC 61850 also offers additional capabilities that future designs may take advantage of. One of these is functional flexibility, or the ability to distribute and assign functions to the optimal device to perform this function. For example, breaker failure protection could be assigned to a protective relay, a bay control unit, or a merging unit. Another is the idea of virtualization and cloud backup in lieu of legacy configuration information formats, storing the XML files for a project as a living and testable as-built document.

Benefits

Benefits of sustainable design are numerous. To highlight some of these:

- Consistency of installations. Field installations are well-vetted by all stakeholders and are integrated with compliance, maintenance, and operations. Supports live no-outage replacements as well as evolution of installations with minimized outages

- Consistency of design. Engineering work is more efficient and productive by shifting from custom project engineering to philosophy and descended standard designs. Documentation and understanding of each installation inherently improves

- Faster project execution. Supports construction and testing elements off site to reduce commissioning time and effort

- Effective, focused training. All designs are described in philosophy and documentation

- Easier event analysis. Installations are consistent and well documented and can be duplicated in a system lab

- More efficient supply chain. Fewer parts and devices, the use of standard assemblies reduces cost and time. Spares inventory is greatly reduced

Conclusion: The direction of the utility is inescapable: more change is coming and coming more rapidly. Inverter-based resource impact the operations of the power system, including PAC functions. More layers of regulatory compliance. More stress on utility systems and more limitations on equipment outages. The rapid application obsolescence and shorter lifespan of microprocessor-based devices. The way to navigate this change in the PAC space is the sustainable design of PAC systems.

Sustainable design means developing an overall PAC philosophy, with standard design documentation, standard physical designs, and a workflow process to manage the development cycle of designs over years. The end goal of sustainable design is simplification and efficiency. Designs are continually repeated to speed engineering and project work, simplify testing and training, and to reduce errors. This simplification is key in the changing environment of the modern utility.

Biographies:

Eric Udren has a distinguished 51-year career in design and application of protective relaying, substation control, communications systems, and synchrophasor measurements in electric utility transmission and distribution systems. He is Life Fellow of IEEE, former Subcommittee Chair and leader of multiple WGs at IEEE PES PSRC, and member of the NERC System Protection & Control Subcommittee. Eric is Technical Advisor to the US National Committee of IEC for TC 95 relaying standards, and charter member of IEC TC 57 WG 10 that develops IEC 61850 standard parts. In 2019, Eric was elected to the US National Academy of Engineering. He is Executive Advisor with Quanta Technology, LLC of Raleigh, NC, and is based in Pittsburgh, PA, USA.

Rich Hunt is an Executive Advisor in Quanta Technology’s Protection, Control & Automation business. He has over 30 years’ experience in the electric power industry with a special emphasis on protective relaying. His focus over the last 15 years has been on all aspects of specifying and designing digital substations, including IEC 61850, process bus, non-conventional instrument transformers, networking, and time synchronization. Rich earned the BSEE and MSEE from Virginia Tech, is a Senior Member of IEEE, a member of the Main Committee of the IEEE PSRC Committee, the U.S. representative to the CIGRE B5, and is a registered Professional Engineer.