By Mario Capuozzo, Doble Engineering, USA

Allow me to introduce myself: My name is Mario. I’m an engineer who daylights as a digital substation product developer, and aside of work, like to engage in more artistic pursuits.

For example, I love making wines and beers. I also spend a lot of time in my two apple orchards, research plantings, where I’m cultivating over fifty varieties of apple trees, with plans to have over 500 trees total by the end of 2024. Today, I’d like to share my love of winemaking with you.

I will not be providing any recipes. For that, I suggest the internet. Tastes vary, so you’ll need to fine tune your recipes to suit yours. Instead, I will describe the general processes, then dive into some more advanced tips and techniques that will aid you in your quest to develop something truly personal, something that you can’t find at the store, because it’s made by you for you.

This is why I enjoy the hobby. Eventually, one gets bored with what they can find at the local store, and no one knows what you like better than you. So, experiment. Go crazy. Don’t accept the established dogma.

Fermentation 101: Let us briefly cover the science before we consider its application in the real-world. In general, alcoholic fermentation occurs when a yeast consumes sugar and produces ethyl alcohol (also known as ethanol) and carbon dioxide, along with many other byproducts.

The alcohol is desirable for its psychoactive properties. Carbon dioxide is desirable because who doesn’t like a drink with bubbles in it?

Like most living things on this planet, yeast partake in the nitrogen cycle. They must consume a source of nitrogen (yeast assimilable nitrogen, or ‘YAN’). Without YAN, there is no fermentation.

This is something that is rarely discussed in beginner guides, but as we’ll see later, controlling nitrogen can be a key component of successful fermentation. Beyond the principal alcoholic fermentation, there are several types of fermentation that can occur in a beer or wine. Some of these may be desirable, and some may be considered “faults” or infections. This is largely based on taste, and what is considered a fault in one wine can be considered a feature in another.

For example, lactic acid bacteria (Lactobacillus) consume carbohydrates and produce lactic acid. They are responsible for the product of sour beers and sour wines.

Other lactic acid bacteria convert malic acid into lactic acid, thus “softening” a wine (malic acid is considered sharper than lactic acid). This malolactic decarboxlyation imparts other subtle flavors, like diacetyl. Chardonnay gets its well-known “buttery” characteristic from the diacetyl produced by these bacteria.

There is even yeast that produce alcohol and lactic acid simultaneously.

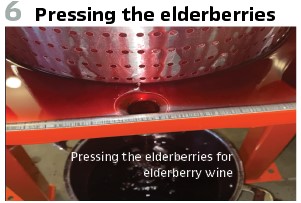

The Process: In brief, to make wine, one must gather fruit juice. We call this the ‘must.’ The fruit juice is poured into a container.

Yeast is added, potentially in multiple stages. Other microorganisms may also be added, such as malolactic bacteria. Alternatively, nothing may be added. Nature has already placed microorganisms all over the fruit. If the must has not been sterilized, one may allow the fermentation to occur spontaneously.

The container is sealed with an “air lock,” which is a device that prevents oxygen from entering the container but allows carbon dioxide to escape as the yeast produce more and more of it. This carbon dioxide will eventually force all oxygen out of the container, creating a “CO2 blanket” which prevents unwanted aerobic microorganisms from gaining a foothold in the container.

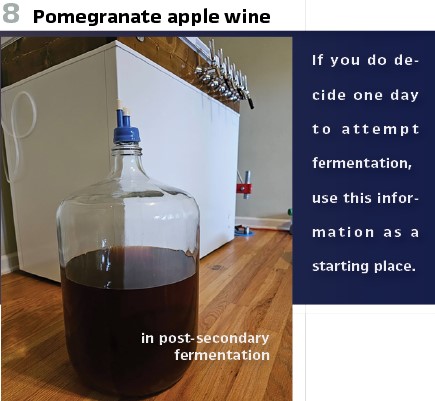

Fermentation will be vigorous at the start. Over several days it will die down as the yeast consume all of the sugar. When this vigorous “primary” fermentation has waned, “secondary” fermentation begins. In this phase, the yeast is eating other things besides sugar (which they have exhausted).

This phase is important in most wines, as it allows the yeast to eat their own byproducts, some of which are unpleasant. If you drink wine that has only been through primary fermentation, it is likely to taste off. We must allow the yeast to “clean up after themselves.”

Once you are satisfied with secondary fermentation, rack the wine off of the “lees” (the sediment of dead yeast cells at the bottom) into a new container. Racking is the process of moving the liquid from one container to another. Often a “racking cane” is used.

Typical wines are racked multiple times, as each time the liquid is racked, a layer of sediment is left in the bottom of the container, so that over time the wine clarifies through sedimentation.

From here, it’s time to bottle. It may also be desirable to carbonate the wine. There are many ways to carbonate a beverage.

The French Champagnes are usually fermented a second time in the bottle. The yeast sediment is later removed in a tricky process known as “disgorgement.” Wines made this way may be labelled “méthode traditionnelle” (the traditional method).

A simpler technique is to “force carbonate” the beverage in a sealed pressurized vessel. And there are other ways, but you get the picture. There are many ways to carbonate. You must choose the method that you find most convenient, the one that provides you with the best results.

Winemaking with Intent: When one makes wine, the goal is to produce a drink that is tasty, shelf-stable, and of a certain percent alcohol by volume.

Shelf stability means the wine bottle won’t turn into a “bottle bomb” and accidentally explode due to unintentional fermentation. To prevent this from happening there are a few simple steps that I will cover later.

Percent alcohol by volume is important. First, it relates to shelf stability. Second, you have some preference for how boozy you like your wine. Play around with this number in your experiments.

Now let’s discuss making “taste” with intent. How does one do that with wine?

It is true that some part of the taste, we cannot control. The fruit we use will be of a certain quality and that’s that. However, even high-quality fruit might need some adjustment to suit our personal preferences.

Often multiple fruit cultivars are brought together so that their characteristics balance each other. In apple wines, there might be 40+ varieties of apples in the mix. Single varietals are the exception, not the rule. And even here in America, wines may be sold as “Merlot,” but contain 25 percent other juices.

This is critical. It gives the vintner the ability to fix a flaw. Perhaps the weather in Oregon was too warm this year and the Pinot Noir wineries need to add a splash of some other grape to achieve their signature flavor. Without the wiggle room to adjust the must, they might suffer.

Conquering taste is important. Thankfully, taste can be quantified! Yes, that’s right. The overall impression of a wine as it hits the tongue and effervesces in the nostrils is something we can fine tune.

I like to divide taste into two categories: signal and noise. Nice engineering terms, I think they fit quite well.

Signal: The signal part of taste (the part that we can control) comes from three principal measurements:

- Total acidity

- Bitterness (tannins)

- Sugar content

We can measure these!

Titratable Acidity (TA) can be measured with test strips or fancy kits from the likes of Vinmetrica. Bitterness comes from tannins in the wine.

For bitterness, we use tannic acid test kits.

Sugar content is measured as Specific Gravity (SG) of the must. If you add more sugar to a juice, it becomes thicker. This is measurable as an increase in its SG. A simple hydrometer will suffice. Though you may also choose to use a refractometer. Both of these can be purchased cheaply.

When it comes time to make the adjustments to hit your target levels, you can use some store-bought ingredients to do so.

To increase acidity, add a blend of tartaric acid, citric acid, and malic acid. The ratios are up to you.

To increase tannic acid, add a tannin powder. They can be purchased online or at your local brewstore. You can even hang a bag of black tea in the must. It will impart tannic acid to the wine and will not leave your wine tasting like tea.

For sugar, I would add dextrose. Some things to keep in mind as you are balancing the must:

- Sugars balance out both acids and tannins.

- Tannins and acids are “frenemies,” I think. Both are desirable in some quantity. However, if you desire a wine that has lots of tannins and body, you won’t want the acidity to be similarly elevated.

Noise: The noise consists of all of the esters and phenols and volatile aromatic compounds that the yeast produces for us. Fruit aromatics may also persist. However, you will find that yeasts do attenuate much of the fruit characteristic during fermentation.

Fruit flavor attenuation is a very complicated topic. Generally, you can select yeasts that are “clean” fermenting, and don’t add a lot of their own complicated aromas. Or you can go with bold yeast that can add untold multitudes of different aromas to your wine.

How do you measure noise? If it’s your first-time making wine, go online and look for some wine yeasts. Then make some wine.

Now, when you enjoy that first glass, when the glass is all the way empty, and all that remains is a light coating of wine on the inner side of it, lift the glass to your nose and inhale. If your yeast weren’t boring and “clean,” you will be greeted with something.

Why an empty glass? Because we have to remove the “signal” to sense the “noise.” When the glass is full, your nose will pick up some of the yeast characteristics, but the other three measurable quantities (acids, tannins, and sugars) are going to overwhelm your senses. With the glass empty (and preferably warmed by our hands), we will get the fullest sensation of what the yeast have been doing behind the scenes.

I can’t tell you all of the amazing aromatics that I’ve produced. From bananas to bubblegum to clove, there is a near infinite number of possibilities with all of the yeast out there. Adjusting sugars and acids and whatnot is quite simple once you know how to make the measurement and know what you like in a wine.

Adjusting the aromatics that the yeast produce involves heavy experimentation. The same yeast will produce two entirely different profiles depending on many factors. Nitrogen content, temperature, pH of the must, the list goes on and on. So, you have to experiment and fine tune your process and try lots of yeast out to really accomplish your flavor goals.

Residual Sugar: The last thing I want to talk about is how to sweeten a wine. Some of us prefer wines that have zero residual sugar in them. These are known as “bone dry” wines. I don’t know why we call wines dry if they have little or no sugar.

The two words “sweet’ and “dry” are not antonyms. I suppose no one wants to say “bitter” or “acidic” when they talk about a wine. Anywho….

Whatever your preference, it is likely that at some point you will endeavor to create a wine that has at least some residual sugar in it. Even a tiny, tiny amount. Why? Because it’s so great at balancing acids and tannins.

So how do you do that? You may think it’s as easy as just adding sugar at the end. But that could be dangerous. Any yeast in your bottle might wake up, start consuming the sugar, and further pressurize the bottle, potentially leading to a bottle bomb. Or at the least, you’ll end up with a sparkling wine where you didn’t intend to create one.

So how do we stop the yeast from eating the sugar in the bottle and producing more alcohol and more CO2? It turns out there are many ways to tackle this problem. Here below I’ll cover the most well-known and commonly used techniques:

- Pasteurization: Did you know Louis Pasteur patented pasteurization not for milk, but for wine? That’s right. He was interested in how to prevent spoilage of wine. However, today, you are unlikely to find any wines that have been pasteurized. This is because adding heat to the fermented wine totally trashes its flavor. All of those subtle aromatics? Gone. You just boiled them into oblivion. Never ever pasteurize your wine unless you plan on mailing it to another galaxy far- far away.

- Preservatives: I’m talking stuff like potassium sorbate, which stops yeast from reproducing. This stuff works. I would never use it, as in my opinion it is bad for your health. And we have other tools at our disposal.

- Cuvee/Kieving/Segmentation Racking.: Yeast need nitrogen to reproduce. If we can somehow remove the Yeast Assimilable Nitrogen from the fermented liquid, we could prevent this. In fact, the French technique of Cuvee (known as kiving in English) accomplishes just this. However, it’s a very complicated technique and I wouldn’t advise it to newbies. Instead, what you should do is monitor your primary fermentation. As it subsides, rack the liquid off of the yeast cake at the bottom and into a fresh container. Lots of nitrogen is locked up in the dead yeast cells in the bottom of the fermentor. By removing the liquid from these cells, the remaining yeast will have less nitrogen to eat. If you do this a few times, at precise moments during the fermentation, you can stop fermentation completely, even with residual sugar.

- Campden tablets: Potassium metabisulfate. Don’t let the name scare you. We’re not talking about a preservative here, at least not in the same sense as potassium sorbate. Sulfur in winemaking has been practiced since ancient roman times, when they would hang balls of sulfur in wine barrels to store them empty. The sulfur prevents microorganism activity. Campden tablets accomplish a similar thing. They produce sulfur dioxide, which binds with oxygen (and also chlorine), thus rendering it unconsumable by aerobic microorganisms. Before you grow concerned about sulfur dioxide, understand that is a naturally occurring chemical. It is found in the grapes and apples that you will be fermenting. The yeast naturally produces it as one of their byproducts. It’s everywhere. Untreated, our wines will have perhaps 10 to 20 parts per million sulfur dioxides in them naturally. I like my wines to be somewhere in the region of 20 to 30 ppm free SO2. The legal limit in the United States is 350 ppm, though most wines you buy will easily be over 100 ppm. You can purchase test strips to measure it, as well as more expensive lab kits, like from Vinmetrica.

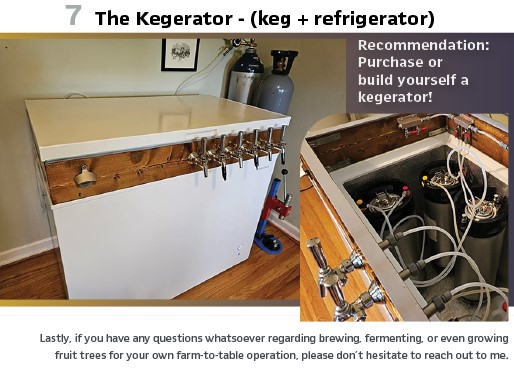

Kegging: One final recommendation: purchase or build yourself a kegerator (keg + refrigerator) or keezer (keg + freezer). They’re a lovely way to control temperatures during fermentation (either in the hot or cold direction). They can serve as fountains for your tasty beverages. I keep non-alcoholic sparkling waters going in mine. I’ve seen people do kegs with cold brew coffee.

They are also useful for the bottling process. You can purchase a counter-pressure bottle filler that attaches to the top and fills your wine bottles under pressure, so that no CO2 escapes from the liquid during transfer.

The Final Word: There is so much more to say about wines, beers, ciders. Whole libraries could be filled with the knowledge, but I hope I’ve piqued your interest with this little bit that I’ve written. Part of the fun will be in the choices that you make, so go and research specific methods and tools to get the job done. Ask yourself how it’s been done before, but then ask how it could be done differently. Don’t settle for the status quo. In essence, you must endeavor to make art.

Biography:

Mario Capuozzo graduated from Virginia Military Institute in 2009 with a degree in Electrical and Computer Engineering and a minor in Mathematics. Upon graduation and following two summer internships with Exelon Generation (formerly Constellation Energy), he immediately entered the power industry, spending most of his time in the field working on protection, control, and automation systems in power plants and substations. In 2013 he went to work for ENOSERV as an application engineer, providing support, training, and field services for RTS and PowerBase.

Following the purchase of ENOSERV by Doble Engineering, he shifted his focus to software development, and currently works as Senior Principal Software Engineer, contributing code to various products, such as RTS, PowerBase, Protection Suite, and the Digital Network Analyzer. Presently he is focused entirely on the modern digital substation and is an active participant at the IEEE PSRC H Subcommittee as well as IEC TC57/WG10, where he helps write standards for the next generation of Intelligent Electronic Devices.