By Rannveig S. J. Loken, Statnett, Norway

This article is based on some parts of the work in CIGRE WG B5.69 published in TB 949, “Experience Gained and Recommendations for Implementation of Process Bus in Protection, Automation and Control Systems” published in 2024 – more specifically findings from review of papers on the topic related to deployment of PACS, and the questionnaire used by working group B5.69.

Overview of publications related to process bus based PACS: Working Group B5.69 collected and classified papers published in the past years describing implementation and characteristics of fully digital substation Protection, Automation and Control Systems (PACS) demonstrators, pilot projects and PACS in large-scale deployment phase. The main support for the identified publications were:

- CIGRE sessions or colloquiums, mainly in Study Committees B5 and B3

- PAC World Magazine. There was a dedicated issue on this subject in September 2018

- PAC World conferences. Papers on fully digital substation were presented there regularly starting from 2017

- DPSP Conferences. Papers on fully digital substation were presented there in 2016, 2018, 2020 and 2022. In 2018, around 10 papers were related to Fully Digital Substations

The following aspects were considered to include projects in the analysis and statistics prepared for the Technical Brochure:

- Projects installed in an operating substation covering the functions of at least one feeder bay

- Feedback from B5.69 questionnaire and / or publications.

In Technical Brochure 949, 195 publications were identified and classified. It is probable that papers on Fully Digital Substations, which have not been identified by the Working Group B5.69, were also presented at other conferences or journals

Review of process-bus based PACS projects

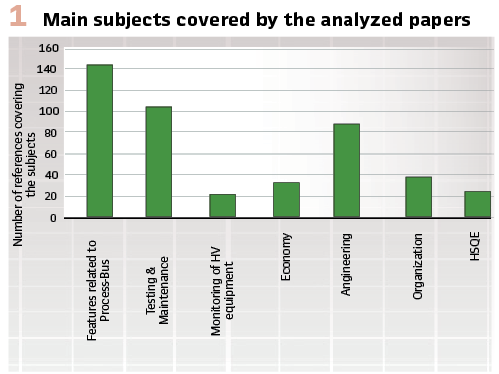

Overview of publications: Figure 1 summarizes the main subjects covered by the analyzed papers. In many cases, one publication discussed more than one of those subjects. Owing to the focus of the analyzed references, most of them cover process-bus related features. Main Subjects covered by reviewed papers was Features related to Process-Bus, Testing and Maintenance, Engineering and Organization.

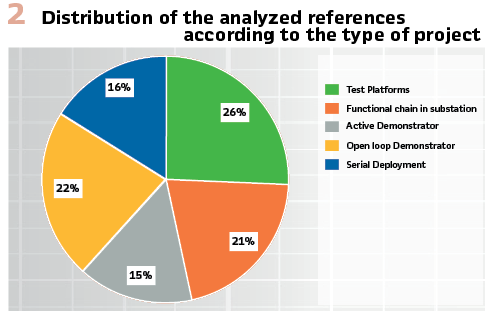

Project characteristics: Figure 2 shows the distribution of the analyzed references according to the type of project. The overall coverage is quite homogenous for the different project types, from open-loop demonstrators to series deployment. Test Platforms cover 26%, Functional chain in substation covers 21%, Active Demonstrator 15%, Open loop Demonstrator 22% and Serial Deployment covers 16 %.

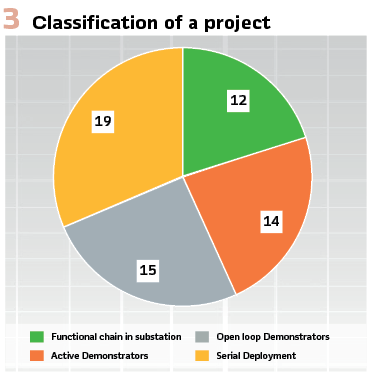

Classification of projects: A total of 55 projects concerning implementation of IEC 61850 process bus were identified. Most projects concern substations from Transmission System Operators (TSO), but there are also some projects on Distribution System Operator (DSO) level. The earlier projects have been mostly initiated by TSOs. As for the publications, it is possible to establish statistics on project characteristics. Figure 3 shows that about half of the identified projects are in service PACS (active demonstrator or series deployment of PACS). Some projects can be associated to more than one project type.

Projects for series rollout can usually be both:

- Functional chain in substation – 12 projects

- Active Demonstrators – 14 projects

- Open loop Demonstrators – 15 projects

- Serial Deployment – 19 projects

Feedback from Survey

Respondents: Whilst a significant number of Process Bus projects have been described and discussed in publicly available literature and at industry conferences, there is also a large number of projects where little or no information is available in the public domain. Publications also tend to focus on specific aspects of a project in line with the objectives of the authors and focus on the chosen conference, journal or target audience. In order to collect some information about these unreported projects and unreported aspects of published projects, a CIGRE survey was conducted.

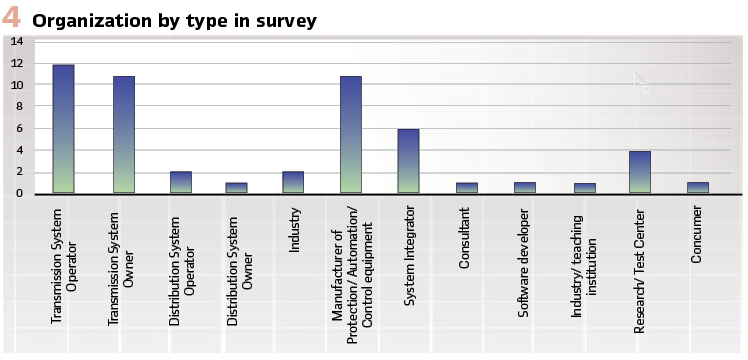

Overall, 42 responses have been submitted by 32 industry stakeholders from 29 companies, departments or academic research institutes. The respondents’ background is mainly technical (83%) whilst the remaining (17%) of respondents are providing feedback from a technical management perspective. Transmission System Operator (12)

Transmission System Owner (11)

Manufacturer of Protection/Automation/ Control equipment (11)

System Integrator (6)

Research/Test Center (4)

Project details and motivation: 33 projects are reported on in the survey related to project details and motivations. Some have been commissioned as early as 2008; however an increase can be observed from 2018 onwards. This reflects the improving functionality and availability of compliant equipment, engineering tools and test tools for process bus applications as well as improved interoperability and compliance with edition 2 of IEC 61850.

There is no specific trend with regards to the voltage level. Process Bus projects were more or less evenly spread over the range of 35 kV to 400 kV with very few applications below 35 kV or above 400 kV. Likewise, there was no strong correlation between the voltage level and the type of project with regards to the connection of trip outputs. Whether to connect trip outputs or not appears to be related to other factors such as level of experience gained and internal technical policy.

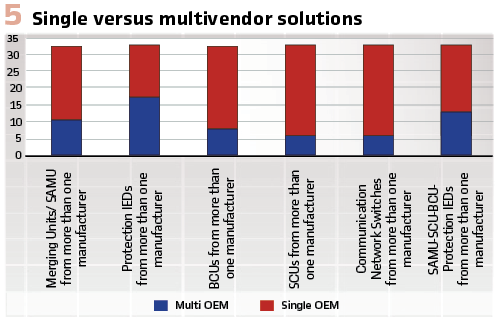

Most projects (21 out of 33) feature at least some level of interoperability requirement. Protection IEDs from more than one manufacturer are used most frequently, which may be driven by internal technical policy in many cases. Merging Units and BCUs / SCUs from multiple vendors are also used in order to demonstrate interoperability and validate the engineering process for multi-vendor solutions. Network switches are in most instances sourced from a single manufacturer as there are fewer concerns about interoperability and common modes of failure. Figure 5 shows the split between single vendor solutions and multi-vendor solutions for each of the categories of equipment for the reference projects in the survey.

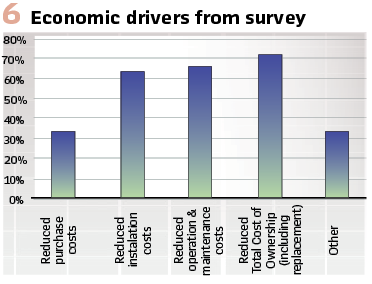

Economic drivers: The drivers and motivations behind the development of Process Bus technology can be varied but do in general include an economic component as shown in figure 6. This will include reduced purchase cost, installation costs, operation and maintenance as well as total cost of ownership considering the effort to replace equipment at the end of its life.

In many cases the cost of LPITs, merging units, IEDs, network switches and cyber security measures may not currently translate into a saving compared to a conventional solution, however there is potential for savings as volumes increase.

It will also depend on what is included in the purchase cost in terms of engineering and installation where savings can be demonstrated. Other economic drivers that respondents mentioned were improved lifecycle management and efficiencies as a result of process improvements such as remote testing and commissioning as well as improved remote diagnostics and audit. (Figure 6).

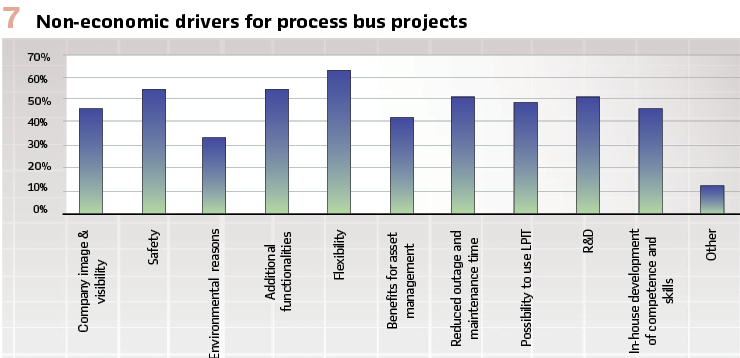

Non-economic drivers: Non-economic drivers for process bus trials and deployments were spread fairly evenly over the proposed options shown in Figure 7. We would still like to point out the following feedback related to flexibility, safety, reduced outage and maintenance time and research and development, all above 50% of the respondents.

Drivers listed under “other” in the survey were in many cases indirectly linked to economic factors such as reduction of wiring, design and engineering work. Interoperability and efficiencies as a result of digitalization were mentioned as well as the convenience of testing Process Bus solutions making use of simulation and the test modes defined in edition 2. The reduction of resources used is also mentioned, which is an important environmental benefit, i.e. reduced footprint, copper wiring, cubicle space etc.

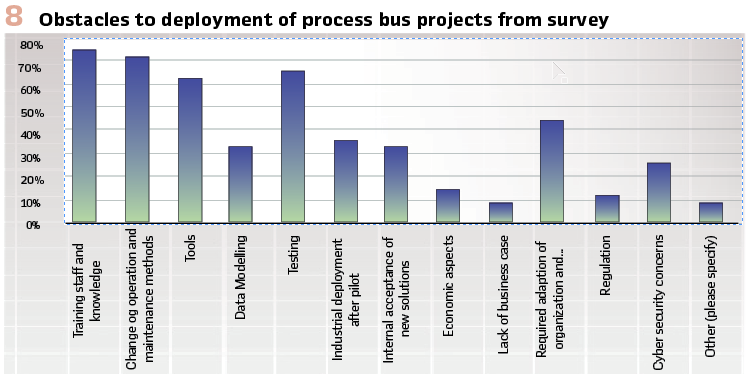

Obstacles to deployment of process bus projects: Some of the main challenges for the deployment of process bus solutions do clearly stand out (see Figure 8). The introduction of Process Bus technology requires a new set of testing and commissioning tools as well as new tools for diagnostics and fault finding. This is a major cultural shift for many organizations and the staff that will require training often have very low availability for training.

Apart from the concerns around training, testing, maintenance and tools, respondents see challenges in the transition to industrial deployment, data modelling, changes to internal processes and internal acceptance as a key obstacle. In order to maximize the value of Process Bus solutions, standardization in design and data modelling are important, as well as the support within each organization to make upfront investments into this technology.

Some respondents have highlighted concerns regarding the economic viability and business case (15% and 9% respectively) whilst regulatory issues are only seen as an obstacle for around 12% of projects. Some additional concerns have been raised under the “Other” category.

The introduction of merging units may add several milliseconds to the overall response time in a functional chain. In some instances, this may be mitigated by the use of heavy-duty contacts for trip outputs but needs consideration for functions where these delays make a significant impact.

The reliability of Process Bus solutions in particular with regards to the use of outdoor cubicles and reliance on GPS and network switches is another concern as well as interoperability and compatibility with future standards/backward compatibility over the lifetime of the equipment.

Experience and key learning points for several categories were reported. Whilst these are brief comments, they will be helpful to share the learning from the collective Process Bus experience gained over the last few years.

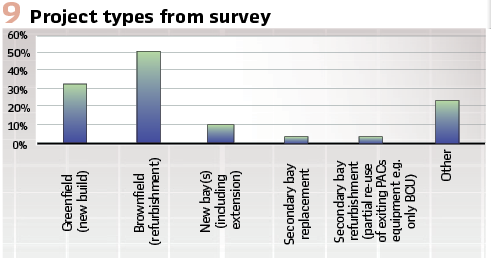

Project types: Deployment options play an important role for utilities, in particular when investigating the overall business case. In general, the business case seems to be strongest for greenfield rollout, utilities tend to have a significantly higher volume of brownfield deployment and bay extensions or replacement projects which explains the high proportion of these (see Figure 9).

Quite a few projects are categorized as “Other” including in some instances additional detail regarding the project type:

- Laboratory interoperability tests

- Complete AIS Bay replacement

- Trial system in parallel to conventional system

- Complete substation retrofit

Project Related Experience

Deployment strategy of digital PACS: The deployment strategy of PACS depends on the project type. For a demonstrator project, the main focus is in general on gaining experience and know-how. For this type of project, it is thus acceptable to have many manual steps for the system and IED configuration. Also, being a unique project, the PACS testing requires adequate test techniques and test tools but would be performed mainly manually.

For PACS intended for series deployment, the users have to streamline the effort for design, test and deployment. This requires top-down engineering and can be supported by using templates for the configuration of the different PACS functions and IEDs, and type tested templates for different bay types.

One important aspect for series deployment of PACS is the efficiency of configuration of the different components. In practice, this implies to import the SCD file, created by the SCT, into one or several IED Configuration Tools (ICT). Template based tests and testing tools using the SCD files to create the test scenarios should be available to automate FAT and SAT of each individual deployed PACS.

For large deployment projects of digital PACS, the most efficient way is to refurbish or build a complete voltage level of a substation. As for conventional PACS, the utilities also have to define the criteria to select the projects. In case of process bus based digital PACS, these criteria may include:

- Feeders or substations to be equipped with LPIT. This may concern substations with Instrument Transformers for which the asset management has identified a need for replacement

- Geographic zones. Concentrating in one region, this may allow to optimize training of operators and maintenance staff

- Substation topologies. The fully digital PACS may not be developed and designed for all existing types of substations

- Implemented PACS functions. Not all PACS functions are required in all substations. The most common functions should be developed and made available first. This needs to be managed

- Monitoring of HV equipment. Process bus based PACS can facilitate the connection of sensors monitoring HV equipment and the collection and transmission of the acquired data. Substations with identified issues on given HV assets may thus be given priority

- Constraints related to asset management and project costs

Recommendations

The recommendations in this article are based on experience gained and lessons learnt from papers related to projects featuring process bus pilot or demonstration Protection Automation and Control Systems (PACS) based on IEC 61850 and from a survey conducted by WG B5.69.

- Cost evaluation: Different drivers and motivations can be behind the development of process bus technology. They include in general an economic component, such as purchase costs, installation costs, operation and maintenance costs and the total cost of ownership. The development of process bus solutions and other costs such as training and commissioning/testing tools will require some initial investment. It can be expected that the average costs of process bus-related components will decrease due to higher purchase volumes. It is recommended to consider the start and end point, long term strategy based on standardized PACS and the total cost of ownership including replacement

- Design and engineering:It is recommended to implement a suitable approach for the design and engineering of process based PACS. In general, it is preferable to develop a new streamlined utility standard rather than transposing legacy utility standards to new process based PACS. It also recommended to implement a top-down IEC 61850 based engineering approach including interoperability requirements

- Serial deployment: For the preparation of a successful serial deployment, it is recommended:

- to develop a proper PACS policy suited to digital solutions

- to develop standard PACS solutions

- to organize proper staff training including familiarization with tools

- to define knowledge conservation policies

- Test strategy: the process bus provides the opportunity to perform a major part of the testing before the site acceptance test. It is recommended to focus on integration tests and FAT

- Commissioning: One of the challenges reported in the survey for the deployment of process bus technology is that it requires a new set of testing and commissioning tools as well as new tools for diagnostics and fault finding

It is recommended to manage the associated major cultural shift and the required training of the staff.

Conclusion

This article is based on some parts of the work in CIGRE WG B5.69 published in TB 949, “Experience Gained and Recommendations for Implementation of Process Bus in Protection, Automation and Control Systems” published in 2024. There is a lot of experience feedback on process bus PACS proving the benefits of IEC 61850 based solutions.

There are numerous projects featuring process bus pilot or demonstration PACS in all parts of the world. Many utilities have adopted a conservative approach trying to gain some experience before committing to a large-scale rollout of fully digital substations. The scope, goals and design of these projects vary widely.

The interest in digital substations is driven by the significant benefits that they offer in comparison with conventional, hard-wired substations. However, the estimated or reported economic benefits show a considerable variation depending on the considered use case, hypothesis, scope and context. Some projects were able to report significant savings, up to 30% depending on the adopted evaluation scheme. These savings are based on a calculation considering industrial deployment and cover the whole life cycle cost.

Other projects were designed as research and development projects to explore the different options and technologies with other goals than project specific savings. The best way to build confidence is by playing with the different components of an IEC 61850 based solution in a laboratory environment. This allows the engineers and technicians to become familiar with the various aspects of the technology without the pressure and the risks of working in the substation environment. The risks can also be limited by open-loop type demonstrators installed in real substations.

Understanding the technology and gaining experience with it helps assessing the benefits of the digital transformation.

Deployment and adoption of fully digital PACS have been slower than what may have been expected, but a huge gain of momentum in the last years has been perceived. This may be partly due to an assessment of benefits and risks on a project-by-project level as well as ongoing developments and learning in terms of the standardization, best practice and technical challenges. Globally, TSOs have started projects involving process bus based PACS earlier than DSOs, but DSOs seem to be catching up now.

The main motivation for DSOs is the use as an enabler for integrated PACS solutions. The central role of the system integrator has been confirmed.

Many utilities are facing a massive increase of workload with new connections, changing flows, reduced inertia, control interaction and new infrastructure requirements. To maximize the benefits from digital technology, after a phase of pilot projects and demonstrators, the technology will need to prove its benefits as part of wider deployment.

A single deployment can be more costly than the conventional baseline solution given the significant initial costs. When assessing the benefits of digital PACS, this should therefore be done in the context of a longer-term strategy considering the long-term deployment schedule and initial costs.

The work of WG B5.69 has shown that there is a lot of experience feedback on process bus PACS proving the benefits of IEC 61850 based solutions. It is recommended that utilities should embrace this technology and take advantage of the associated benefits.

Biography:

Rannveig S. J. Loken. received her Master of Science in Electric Power engineering from the Norwegian University of Science and Technology (NTNU) in 1992. She works in the Protection department in Statnett, the TSO of Norway. In August 2024, she became CIGRE Vice-president Technical. Her special field of interest is protection and control for the transmission system. In addition, working in Cigre Working groups is of great interest – she is currently a member of WG B5.86. Rannveig is in the Advisory board of PAC world, and Committee member of IET DPSP.