By Kalina Barboutov, Hitachi Energy, Switzerland

Since North America’s first advanced metering infrastructure began deployment around 20 years ago, there has been no uniform path toward distribution automation. Numerous vendors have developed countless technologies to improve distribution grid control at critical points, and they have connected them with an array of communications technologies and protocols.

Today in North America, the concepts of grid modernization and distribution automation are, in practice, a hodgepodge of comms and control applications enabled by fleet devices with different technical capabilities and limitations.

And yet, a standard approach is emerging. As the pace of decentralization, decarbonization and digitalization increase rapidly in North America — particularly in the United States, given federal funding for distributed generation, electric vehicles and other clean energy infrastructure — the need for grid asset management simplicity has become paramount. Already dense distribution grids are getting even denser. The number of assets connecting to the grid is exploding, and so, too, are the number of decisions grid operators must make daily to manage the growing complexity of the distribution grid. DSOs need their disparate fleet devices and communications protocols to converge into one system where a single decision from a grid operator can cascade across the fleet so that subsequent actions are then taken automatically.

Fleet Devices

Before diving into distribution automation — and fleet management models to enable it — it’s essential to define fleet devices clearly. The grid comprises assets that include conductors, reclosers, breakers, feeders, capacitor banks and transformers, to name a few. They are the functional elements of the grid that carry power flow (and hence can be represented by a line diagram), they are traditionally managed by NIS (Network Information System) or GIS (Geographical Information System), and their operations are often based on SCADA systems. These operational grid assets do not have advanced intelligence or complexity; therefore, they do not need comprehensive firmware, security, or performance management. Because they have been functioning in grids for decades, we do not foresee a deployment boom triggered by decentralization and decarbonatization of these asset types.

To accelerate the automation and operational efficiency of grids, traditional assets are now accompanied by a variety of intelligent control and communication assets, which we will call a “fleet.” RTUs – wireless and wired communication devices which can compute, execute, and communicate complex logic or policies – require a different type of management infrastructure: one that can deploy, audit, and manage complex and periodic firmware changes, configuration, security, and performance activities. This is referred to as a “fleet management system.” In essence, a fleet is a collection of grid assets that do not carry power flow but serve a fundamental purpose of control and communication, which allows DSOs to operate traditional grid assets in a more effective way. Intelligent fleet devices are what help DSOs address the challenges posed by decentralization, decarbonization, and digitalization.

The Evolution of Distribution Automation

Distribution automation refers to any automation in a distribution power system, including interactions with the transmission system, interconnected distributed energy resources (DERs) and automated interfaces with end-users. It can range from monitoring and controlling the primary equipment at the substation level, local automation of fleet devices on feeders, and managing DER systems to advanced metering infrastructure integration and demand response.

For most of its history, the distribution grid has been mechanical, unconnected and relatively unmonitored. Very little was done to optimize performance, to the point that DSOs were dependent on customer calls to inform them that power was lost. Even in the more advanced markets today, there is only slightly more automation and intelligence. However, the number of initiatives and projects to unleash grid modernization capabilities has grown exponentially.

The primary drivers for extending automation deeper into the distribution grid, and toward the grid edge, are the increasing penetration of distribution generation from renewable sources of power, the electrification of transportation, and fluctuating peak electric demand times due to the increased number of demand sources like electric vehicles (EVs) and home battery systems.

One of the main benefits of extending automation through digital substations and fleet devices is providing situational awareness for DSOs, allowing them to literally see the behavior and condition of their network.

Extension of automation toward the grid edge helps DSOs alleviate enormous strains on their electrical grids from the emergence of renewable energy sources being fed into the grid. Intelligent fleet devices can be used to stabilize voltage control for grids as power from photovoltaic installations, wind turbines and other DERs integrate into distribution systems.

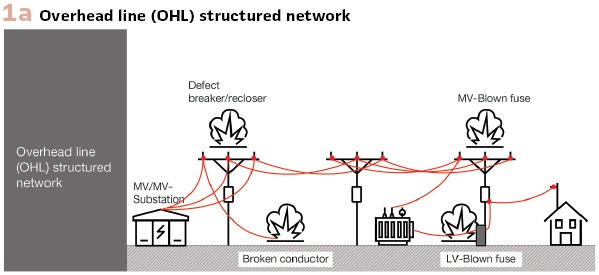

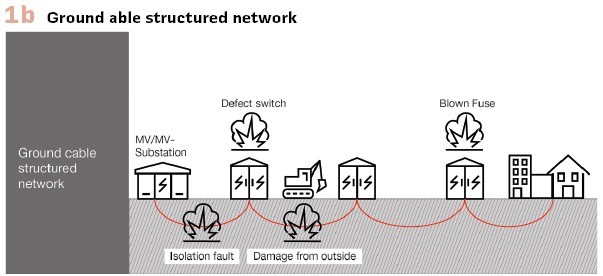

Automation also helps DSOs reduce operating costs by reducing downtime and grid failures. Natural or component failures in the power distribution network can be due to multiple causes, such as falling trees, overhead lines falling to the ground, or poor insulation of isolators. DSOs are seeking solutions to reduce monetary loss from failures and duration of outages, and grid automation has the potential to dramatically reduce downtime. (Figure 1a/b).

Network automation solutions help reduce the number and duration of outages irrespective of whether lines are located above or underground. Feeder-based fault detection isolation and recovery (FDIR) is an automated process performed to enable a rapid response to a troublesome feeder and substantially reduce the number and duration of failures in the distribution network.

Technological advances over the last decade in the areas of sensing, data processing, control, and communications also have allowed DSOs to advance to model-based Volt/VAR optimization (VVO) methods, which can mathematically optimize for voltage and reactive power across the grid, in its current configuration. A VVO solution relies on some core technologies and infrastructure to utilize the many sensors and actuators in the grid:

- Distribution management system (DMS) containing the network model

- Supervisory control and data acquisition (SCADA) system

- Two-way communications

DSOs are looking to benefit from the latest technological advances in the distribution automation field to bring about the next step-change benefits, and there are two main opportunities available.

The first is to increase the penetration of their existing automation infrastructure further into the distribution grid. Depending on the grid topology, this can mean extending automation downstream from primary distribution substations into the medium voltage feeders, or perhaps to the secondary distribution substations. Increasing the utilization of automation enables greater operating cost savings through greater visibility into the real-time state of the grid, finer control, and functionality such as automated FDIR and VVO.

As mentioned, extending automation deeper into the distribution grid introduces many new fleet devices, operating protocols and communications standards. In turn, these can require many more decisions and actions of grid operators. While automation significantly benefits DSOs, the sheer volume of devices needed can render the solution too large to manage.

The second opportunity is to increase the level of integration of these fleet devices, protocols and communications standards. To reduce complexity and increase interoperability, DSOs should seek convergence to bring devices and protocols together. To do so, they require an information technology (IT) infrastructure that serves a multipurpose function. It enables distribution automation to contribute to simplified, effective grid operation designed to ensure reliability and scale with growing decentralization, decarbonization and digitalization.

For most DSOs, dependence on IT will continue to increase, especially with the increased digitalization of the grid and the complexity of data handling associated with it. Digitalization and data management make it more critical for various IT and operations technology (OT) systems to be seamlessly integrated. To achieve that outcome, IT needs to be aware of operating requirements in the field, which can be quite different from enterprise IT requirements. The efficiency gains that this integration achieves within DSOs allow them to leverage yet more benefits from the automation of the distribution grid.

The Management of the Integrated Fleet

Integrated fleet management is one such example of integration unleashing new benefits of distribution automation, and it is likely to lead a new wave of grid modernization investments by DSOs.

Fleet management is currently conducted as previously described: Grid operators manage their fleet devices by making more decisions and taking more actions due to the fact the devices can’t operate on different systems with different protocols and different communications standards.

However, integrated fleet management solves the problems of disjoined distribution automation technology by converging their operation into a single management platform.

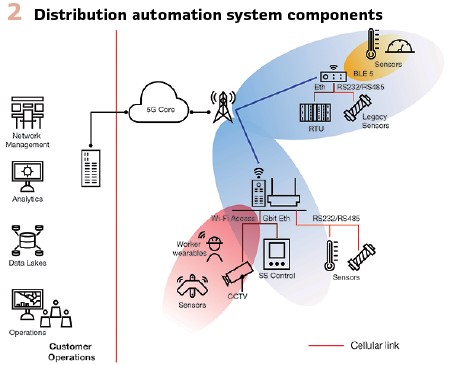

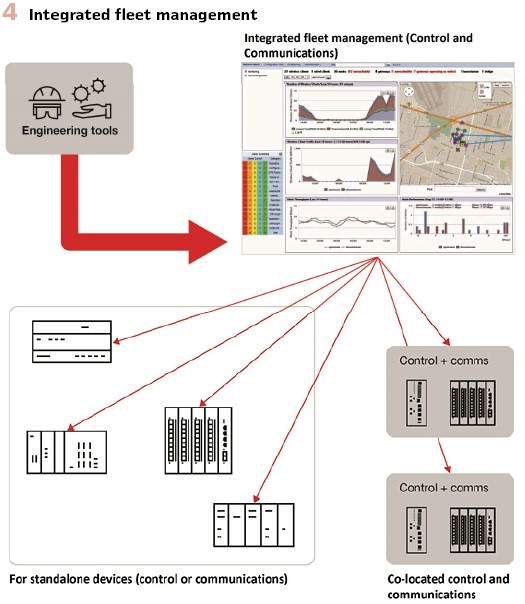

A primary challenge facing DSOs is that grids contain a large number of legacy devices that use a diverse range of media and protocols. Over time, it becomes complex and expensive to manage and scale networks with such architecture. However, 4G and 5G allow software-based solutions that converge networks and — with the help of industrial communication devices that have multi-technology capability — vastly reduce the cost of automating grids without the need to rip and replace the legacy equipment. (Figure 2).

Too Many Local Network Stations, Too Little Time

Modernizing the distribution grid presents a huge scale challenge, given its density with all the assets and legacy devices. Looking at the grid in one of the geographically smallest countries in the world illuminates the issue.

There are only three DSOs in the Netherlands, compared to hundreds in the United States, and they operate a total of about 70,000 secondary substations. Of those substations, about 20% are automated today, or roughly 14,000. Dividing those evenly, each DSO has around 5,000 automated substations.

A comprehensive rollout of grid control and communications requires careful planning and implementation. Even using best practices for efficiency such as rollout templates or pre-configured control cabinets, DSOs face difficulties in a broad rollout. Even under the optimistic assumption that an average of two stations can be equipped per day, it would take years for 5,000 stations to be installed.

But the real scale challenge comes after control and communications fleet devices have been rolled out. The network operator usually requires that the supplier provide security patches and bug fixes for a period of at least 10-15 years. Given release cycles that are typically between 6 and 12 months, this means that every station must receive an update at least once a year – and that’s at the very low end of estimated yearly updates. Given that new cyber threats can emerge at any moment, even multiple times per day, it is obvious that a manual initial configuration and manual updates cannot be performed on-site or remotely. Based on this situation, further questions arise, around the robustness of the firmware version currently used on the devices, the configuration of the systems and the status of the communication network.

Integrated fleet management is required to answer these questions. A web-based fleet management platform enables joint management of telecontrol devices, communication devices and the associated network. Construction of such a network is relatively simple because all settings can be managed and distributed centrally at scale.

This low-touch approach makes it possible to activate and expand a functioning network within a short time. Efficient management and distribution of configuration settings ensure smooth commissioning. Device configurations, managed by the fleet management platform, are stored and distributed centrally.

Monitoring the network and connected devices in real-time is the other side of the coin. An intuitive web-based fleet management platform interface can visualize network performance and reliability while minimizing planning, deployment and ongoing management costs.

Regular statistics of important network parameters — such as disconnections, packet loss or network congestion — can be recorded and displayed, providing DSOs insight into the status of the network in real-time. All data collected is stored in a database and can be used for detailed drill-down and trend analysis.

Breaking Down the Benefits of Integrated Fleet Management

At the highest level, integrated fleet management is the next step in the evolution of distribution automation. Disparate devices, protocols and communications standards have increased complexity for grid operators when distribution automation is needed to make grid operations simpler and more cost-effective.

Integrated fleet management solves the big problem and in doing so unlocks four key benefits of automation for DSOs.

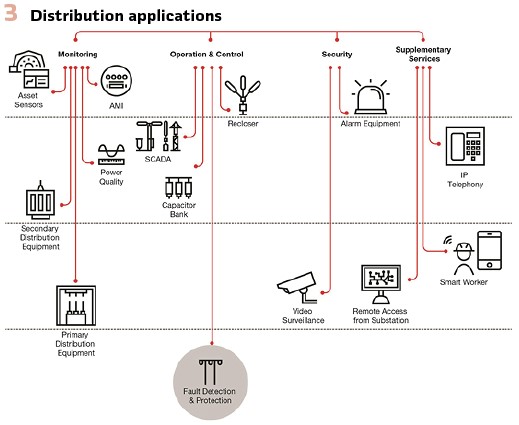

1. Distribution applications: DSOs today need to add more and more applications to their grid operating capabilities across functions, including monitoring, operation and control, physical security, and supplementary services. By employing intelligent devices, DSOs can add more applications to the grid without adding expensive new hardware. Integrated fleet management is the practical means to add applications and configure them to the network at mass scale. (see Figure 3).

For example, an increasing number of DSOs want to implement grid edge-compute applications that can be very specific and may not be standardized – one such example may be the translation of proprietary protocols to mainstream grid protocols. The easiest way to mass implement functions is through a fleet management platform sending the updates through the network’s communication devices.

2. Cybersecurity: Energy infrastructure is critical to national security, and thus it has become subject to substantial new cybersecurity regulations. These regulations mean DSOs can face huge penalties for failing to update their systems against new cyber threats. This is a challenge for DSOs because cyber threats — and therefore cybersecurity — change every day. It’s not unusual for infrastructure operators to feel their systems are completely secure one day only to discover they’ve been hacked or highjacked the next. DSOs need the capability to update their systems as often as necessary to ensure security, avoid ransomware and loss of service and productivity. Integrated fleet management is the only approach to keep pace with the needs of cybersecurity across tens of thousands of connected devices.

3. IT/OT convergence: No longer can IT sit in the office while OT sits in the field. With the increasing density of the distribution grid, driven by field devices deployed in OT’s traditional physical domain and using IT skills to harness them, the line between the two has been blurred. That trend, however, is a good thing that DSOs should encourage. The convergence of OT and IT benefits both groups, as they share industry knowledge and technologies across their old silos. However, creating a smooth convergence requires more configuration and parameterization. Rather than being governed solely by traditional grid protocols such as IEEE, grid control and automation now must be governed end-to-end with full technology stacks for issues such as cybersecurity. IT cannot simply ruggedize enterprise solutions and send them out into the field. DSOs need more robust tools to converge IT and OT as needed, and integrated fleet management allows them to successfully deploy, manage, upgrade and maintain network configurations.

4. Better metrics: Distribution grid reliability performance metrics such as system average interruption duration index (SAIDI) and system average interruption frequency index (SAIFI) are critical to every DSO. These metrics not only measure how DSOs deliver reliable electricity, they are also used by regulators to judge DSO performance and how much grid investment to authorize. A challenge with traditional reliability metrics such as SAIDI and SAIFI is that they were not designed to measure reliability issues that couldn’t be tracked before digitalization and increased visibility came to the grid. Thanks to modern grid technology, new reliability performance metrics will emerge as DSOs and regulators are able to track a more complete picture of reliability. Ultimately, these new metrics will allow DSOs greater visibility in their networks, and integrated fleet management will give them the ability to further optimize —resulting in better service for customers and more effective operation of the distribution grid.

What’s Next?

The future is now for integrated fleet management in North America.

Fleet devices for control and communications are already widely deployed in distribution grids across the continent. And compared to other geographies, North America has an abundance of choices for the high-speed, broadband wireless communications needed to effectively and cost-efficiently utilize a fleet management platform.

The infrastructure required to deploy integrated fleet management is there, and so is the business case. 5G technology has come to North America much faster than industry experts predicted just a few short years ago. As such, the industrial internet of things (IoT) has arrived on the distribution grid much faster than expected. DSOs are rolling out initiatives and pilot projects that will deploy millions of industrial IoT devices with the good intention of using them to maintain a reliable grid against the challenging forces of decentralization, decarbonization and digitalization. However, if there’s no unified platform to manage fleet devices, the number of decisions and actions required of grid operators becomes untenable.

While many DSOs today have a strong preference for housing software on premises in operations centers, the future of integrated fleet management will likely migrate to cloud architecture very quickly because it is easier to scale and may be the only way to match the vast growth in application needs. (see Figure 4).

The idea of investing in thousands or millions of control and communications fleet devices plus cloud-based fleet management software is overwhelming for many DSO leaders, given how little change has historically taken place on the distribution grid.

But fear of change is not a solution. No DSO leader questions that decentralization, decarbonization and digitalization are catalyzing an “adapt or die” moment for reliable grid operations, nor that distribution automation is the right path to adapt. What should, then, be equally clear is that the only way to lead this adaptation effectively and cost-efficiently is through the high-level automation enabled by a solution like integrated fleet management.

Biography:

Kalina Barboutov leads Hitachi Energy’s Distribution Automation solutions business globally. With over a decade of 4G/5G and emergency communications experiences across four continents, Kalina joined Hitachi Energy (ABB’s Power Grids division), a world leader in transmission grids, in 2019, leading their wireless communications team. In 2022, she took on the challenge of leading the distribution automation technical expertise function – a new and rapidly expanding business for Hitachi Energy. In her current role, Kalina looks after control, communications, medium voltage protection, and network management systems. With her global experience across multiple industries, Kalina and the Hitachi Energy team focus on solving customer business problems through innovative products and solutions that future-proof DSO investment and technology bets.