PAC World: When and where were you born?

J.McD.: I was born in Gary, Indiana on 22 December, 1951. The same doctor delivered my Dad in 1927, me in 1951, my brother in 1953 and my sister in 1961.

PAC World: Where did you grow up and where did you go to school?

J.McD.: I attended two elementary schools in Gary and middle and high school in Arlington Heights, Illinois, a suburb of Chicago.

PAC World: Did you have any specific interests while in school?

J.McD: Sports and electricity. My first sport was Little League baseball. Basketball in middle school. Football and baseball in high school. At Purdue University I played competitive handball and table tennis. While living in San Francisco I played fast-pitch softball and flag football. In fifth grade I became interested in electricity. I read, learned to solder, built a short-wave radio, walkie talkies, and a code oscillator, among others. By high school I took courses and built a superheterodyne AM/FM radio, and replaced the picture tube in a black and white TV.

PAC World: Where did you go to university and why did you choose that one?

J.McD.: I wanted to study Electrical Engineering, but despite having an Illinois state scholarship with in-state tuition at the University of Illinois, I visited Purdue University first. Without an appointment, the director of admissions met with us and answered all our questions. I fell in love with Purdue that day. I earned my bachelor’s degree in electrical engineering in 1973 and my master’s degree in electrical engineering, specializing in power engineering, in 1974.

I attended the University of California-Berkeley at night for an MBA degree, specializing in finance, graduating in 1978.

PAC World: Did you study anything related to power system automation while in university?

J.McD.: No. At Purdue, I was in the honors program and Professor Ahmed El-Abiad – who had just co-authored a book on using digital computing to model and analyze the power system – laid out my curriculum, with a focus on power engineering. His guidance meant that I took courses in electrical, mechanical, and nuclear engineering. Professor El-Abiad felt that a power engineer should be multi-disciplinary. My focus at Purdue was on computer methods in power system analysis rather than power system automation. My master’s thesis was (I think) the world’s first Three Phase Load Flow Program using Cartesian coordinates and the Newton Raphson solution method, which was published in the IEEE Transactions on Power Apparatus and Systems in 1976.

PAC World: Where did you start your career and how did it happen?

J.McD.: I started with Bechtel Corporation in San Francisco in 1974. I interviewed with many companies while at Purdue while completing my master’s program. I had worked summers and holidays on power engineering and wastewater treatment design at Consoer, Townsend & Associates in Chicago. When I interviewed with Bechtel at Purdue, its work was similar. The intensive interview process to match my interests to an employer opened my eyes. I had never been west of Illinois. To live and work in downtown San Francisco seemed adventurous. Everything was new.

PAC World: Why did you decide to continue your education in finance?

J.McD.: I knew that specializing in a finance MBA would help me with my full-time engineering work. I see many excellent engineers today failing to get approval for their engineering projects because they are not able to develop a viable business case for their technical project.

PAC World: How did you become involved in the development of energy management and control systems?

J.McD.: After nearly five years with Bechtel Corporation, I joined Brown Boveri Control Systems, Inc. (BBCSI) in Santa Clara, California, in 1979. The parent company Brown, Boveri & Compagnie (BBC) was a power engineering company with a new SCADA subsidiary. I became the first power engineer in BBC’s SCADA subsidiary. That role introduced me to the development of energy management and control systems. On my first day, the top executive told me that BBCSI was short listed on a $1 million proposal for a SCADA/Automatic Generation Control (AGC) system for a Midwest municipal utility. The proposal included four power system applications: Automatic Generation Control, Economic Dispatch Calculation, Interchange Transaction Scheduling and Interchange Transaction Evaluation (Economy A and B). BBCSI had a meeting scheduled in one week with a consultant steeped in power system application experience. BBCSI had no previous experience with SCADA/AGC systems. I had one week to learn about SCADA and the four power applications to convince the consultant that BBCSI could successfully perform the project. We won the project.

PAC World: After about 15 years work on energy and distribution management systems (EMS/DMS) you decided to become a consultant. What triggered the change?

J.McD.: By 1995, if you add in another four years working for McGraw-Edison Power Systems, I had worked on SCADA/EMS/DMS for 17 years. I had been active in the IEEE PES Substations Committee, leading standards development in substation automation and communications protocols. I had been active in developing the Utility Communication Architecture (UCA) in North America, later integrated with Europe’s IEC 61850. I knew a lot of people across the power industry. I had never thought about going into consulting. But I felt well prepared to leverage my experience in a new way. I wanted to stay in Atlanta. Through a friend, I learned of a need at the precursor to KEMA Consulting and signed on in 1995.

PAC World: In 2007 you joined GE Energy and you have been there since then. What led you to work for a manufacturer?

J.McD.: By 2007, I had enjoyed working for KEMA Consulting for 12 years and thought I’d do that for the rest of my career. A friend alerted me to an executive level position open at GE, reporting to the CEO of its T&D business. With changes underway at KEMA, it seemed like a good time for a career change.

When I interviewed at GE, I was 56 years old, with 34 years of experience in T&D and 17 years of experience with three automation system suppliers. I had held many leadership positions in IEEE, IEEE PES and IEEE-SA. I had vastly more experience than anyone in the GE T&D business. GE’s executive team saw the value I could bring to their business. Thus, I started working for the largest company in my career at the end of my career, which is the opposite of what I recommend to young professionals.

PAC World: You had started working with RTU-based EMS and have seen the transition to IEDs and integration-based systems. Was that transition difficult?

J.McD.: Yes. Our focus, for decades, was on data the RTU collected, processed, and sent upstream to the operators in the control center. With the advent of IEDs, we had two different types of data in the device to manage. However, our expertise, business processes, and organizational structure and skill sets were based on the traditional RTU data flowing to the operators. IEDs produced data that was not being utilized. The industry simply wasn’t prepared to use it.

Eventually, the industry had to transition from an RTU-centric substation architecture to a network-based, distributed architecture with IEDs and data concentrators that could also route non-operational data to business groups across the utility. At that time, I led the IEEE PES standards development in substation automation as the IEEE PES Substations Committee Subcommittee C0 Chair. When we updated IEEE Std C37.1 (for SCADA) in the early 1990s we introduced the term “Intelligent Electronic Device (IED)” so we would have an industry-wide term for the new devices.

I introduced the concepts of operational and non-operational data in a guest editorial I wrote for IEEE Power & Energy Magazine (March/April 2003) titled “Substation Automation: IED Integration and Availability of Information.” Even today, utilities are not realizing all the potential benefits from the available non-operational data throughout their enterprise. Sorry, I can’t stop evangelizing for non-operational data!

PAC World: During the more than 40 years of your career what was the most challenging project that you have been involved in?

J.McD: When I joined BBCSI in 1979 and helped win the SCADA/AGC project with a municipal utility, BBCSI had no power application software and no experience with SCADA/AGC system projects. I had to source the four power application software programs we needed, then integrate them with our SCADA platform. I spent two months at corporate parent BBC in Baden, Switzerland, evaluating their power application software. Meanwhile, the project had already begun. I learned that Power Technologies, Inc. (PTI) in Schenectady, NY had developed the needed power applications for a utility in the Midwest, and they would run on the identical computer platform as our project. I licensed the four applications from PTI, did source code training at PTI, then worked with our software programmers at BBCSI to integrate the four applications with our SCADA platform. Since this was a “first” for BBCSI I wrote the documentation, test procedures and training material. I was 27 years old and had learned about SCADA and these four power applications a few months earlier. This was a very challenging project, with a lot of pressure to succeed, and we did.

PAC World: And the most satisfying one?

J.McD.: During my years with KEMA Consulting, three SCADA projects stand out:

One was a municipal utility, which had never had SCADA and lost a substation to a transformer explosion. I guided their SCADA implementation and substation automation.

Another muni had SCADA, but it relied on a proprietary communications protocol from a defunct supplier. I helped them replace the SCADA master, implement substation automation and use protocol converters to use an industry standard protocol.

The third was a municipal agency with aging SCADA and a very slow scan rate. They needed a more accurate indication of customer load because they sold the difference between their generation and load on the open market. The new SCADA system we implemented paid for itself in months.

PAC World: You have been actively involved in the development of the Smart Grid. How did that happen?

J.McD.: Actually, when the term “Smart Grid” first appeared, I took offense to it. Adding intelligence to the electric grid was not new. Many of us had been adding intelligence to the grid for decades. At Purdue my focus on digital computer modeling and analysis was truly new. I spent 46 years of my career on power system automation – adding smarts. So, I developed a PowerPoint slide I call the “Smarter Grid,” which reflects already existing intelligence as well as the intelligence we were adding as part of “Smart Grid.” It is important to recognize this point.

PAC World: Do you think it is time to move from steady state estimation to steady state observation based on synchrophasor measurements?

J.McD.: SCADA data is typically sampled every 2 to 4 seconds. Synchrophasors, measured by Phasor Measurement Units (PMUs), are 100 times faster. PMU measurements record grid conditions with great accuracy and offer insight into grid stability. Synchrophasor technology is used for real-time operations and off-line engineering analyses to improve grid reliability and efficiency and lower operating costs. We have only begun to realize the total benefits of using both SCADA and synchrophasor data.

PAC World: In the last 25 years we have been developing IEC 61850. It is used today in thousands of substations around the world. What do you think about its role in the Smart Grid and why are some people still not using it?

J.McD.: The need for standard communications protocols and networking exists at three levels. For control center to control center data exchange, the one global standard is the Inter-control Center Communications Protocol (ICCP). For control center to field communications, the two standards globally are IEC 870-5-101 and 104 for European suppliers and IEEE 1815 (DNP3) for North American suppliers. For communications within the field, North American suppliers and utilities use IEEE 1815 (DNP3) and are beginning to adopt IEC 61850. The remainder of the world uses IEC 61850 to a much greater extent. I’ve seen a lot of global convergence in the past 25 years.

Globally, except for North America, utilities are comfortable with turnkey substation projects. Utilities in North America have standardized on one supplier’s protective relay, a different supplier’s transformer monitoring and diagnostic device, yet another supplier’s tap changer monitor and control. With the turnkey approach the supplier has full control over all components, therefore it’s much easier to implement IEC 61850, due to long-established interoperability of components. The North American approach requires an integrator. That poses more risk due to potential lack of interoperability and that hampers greater implementation of IEC 61850.

PAC World: When and why did you join the IEEE?

J.McD.: I joined IEEE in 1971 as an undergraduate EE student at Purdue. When Professor Ahmed El-Abiad suggested that we join IEEE, we didn’t question him! Looking back, it has been invaluable to my career and 2021 marks 50 years of membership!

PAC World: You have been very actively involved for many years at all levels of the IEEE PES. How did you manage your high-level management positions at GE with all your responsibilities at the top levels of the IEEE PES?

J.McD.: Briefly, it’s about time management and staying ahead of deadlines to do quality work for either job or volunteer work. When collaborating, reach out early. My professional roles enabled my volunteer work, just as volunteering advanced my career. And I manage these two roles in order to enjoy family time and respond to collegial requests for help.

PAC World: You are still very active also in CIGRE. What do you think is its role for the electric power industry compared to IEEE?

J.McD.: The two organizations are complementary by having different approaches. First, CIGRE taught me a more global perspective on technology, as functionality and business cases differ by region. Second, participation in CIGRE by C-level executives translates to global networking opportunities. Third, CIGRE’s focus is practical, not academic. Though IEEE is moving towards the policy implications of technology choices, it has vast and deep technical expertise. I would contrast them, but not compare them. Long ago I realized being a “complete” power engineer requires active involvement in both.

PAC World: What do you consider your greatest professional achievement?

J.McD.: All the education and professional work I’ve done has enabled me to help others. No matter how busy I am, I will find time to help others succeed, without expecting anything in return. I’ve earned the opportunity to pay back the help I’ve received.

PAC World: What do you consider your greatest personal achievement?

J.McD.: Being happily married for over forty years with two children who are both happily married, and having two grandchildren. I’ve managed my work/life balance, including extensive travel, in order to participate in my family’s activities. By extension, that includes my own, my son’s and my volunteer participation in Cub Scouts and Boy Scouts, as well as promoting STEM education for girls and boys.

PAC World: You have received many awards. Is there a specific one that you consider the most important?

J.McD.: Two stand out. I was named an IEEE Fellow in 2003 “for technical leadership in the development of substation integration and automation.” I helped pioneer the field of IED integration and substation automation and being named an IEEE Fellow recognized that work.

I received the IEEE PES Meritorious Service Award in 2015, bestowed by past winners for those who’ve made outstanding contributions in leadership, technical activities, and educational activities of IEEE PES. That was humbling. And now I’m chair of that award committee.

PAC World: You have so much knowledge and experience. How do you share it?

J.McD.: I write, talk, teach, travel and mentor. After nearly 50 years in the business, I have assembled my thoughts on career decisions in a talk titled “Key Insights to Career Management,” to help young professionals.

PAC World: Is there anything you would like to say to the young PAC engineers around the world?

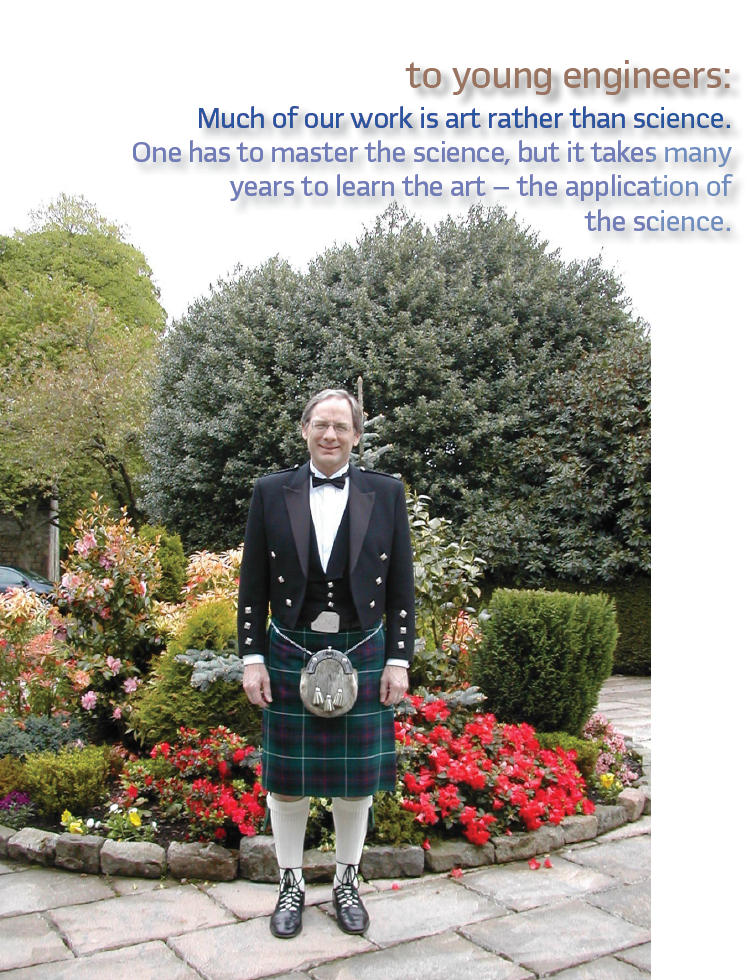

J.McD.: Much of our work is art rather than science. One has to master the science, but it takes many years working with very experienced people to learn the art – the application of the science. Young PAC engineers should find at least one mentor and spend at least one hour with each mentor each month to learn the art of protection, automation and control.

PAC World: You have been married for more than 40 years. What is the secret?

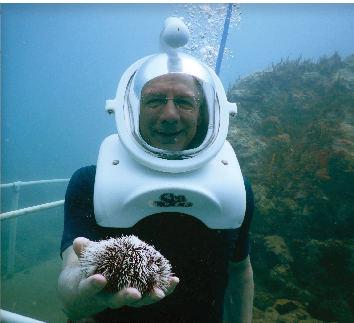

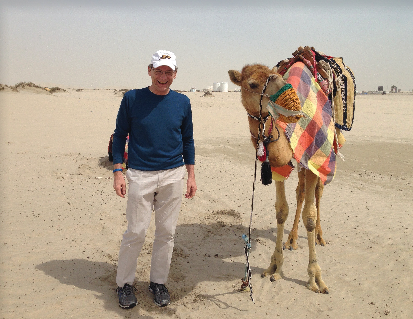

J.McD.: My wife, Jo-Ann, is a residential interior designer so it is true that “opposites attract.” It’s important to include your spouse in all your activities. Communication is so important. When I started working from home in 1995, she became familiar with my work and my colleagues. And Jo-Ann travels with me on most international journeys.

PAC World: Your favorite form of entertainment?

J.McD.: International travel with Jo-Ann. Time with our three-year-old golden doodle, Bruno, who hangs out with me in my home office. Cooking and baking, if you can believe it. I use Spotify to listen to my favorite songs from the 1960s and 1970s. Activities that relax me.

PAC World: What about food. Any preferences?

J.McD.: Jo-Ann pointed out to me, shortly after we met, that my driving directions always hinged on eating places! I enjoy food and the feeling is mutual. My favorite food is any dessert with coconut.

PAC World: You travel all over the world. Do you have a favorite place to visit?

J.McD.: I have flown over 4.25 million miles so far. My memorable trips are those that defied expectations — Iceland in December, Armenia after independence, working construction outside in northern Alberta during winter. (These may not be Jo-Ann’s favorites.) Lastly, Scotland. After a project there in the ‘90s, my family began taking vacations there. My family roots are on the Isle of Skye, where there are more sheep than people. I finally got to wear a kilt with the Dress MacDonald tartan at a colleague’s son’s wedding in Edinburgh. I’ll never forget that day, nor will others!

PAC World: Can you ever imagine retiring?

J.McD.: No. I haven’t thought about retiring. I am 68 years old and having more fun now than ever in my career.

PAC World: Is there anything that we didn’t ask you that you think can help our readers better understand who you are?

J.McD.: I reached the peak weight in my life at the end of 2010, when I turned 59 years old, after eating all the sweets available during the holidays. At the behest of my son and daughter, who knew my inner athlete, I began working out with a personal trainer, a former star for Georgia Tech, the Chicago Bears and Atlanta Falcons. He taught me to eat healthy foods, practice portion control, and exercise regularly. I am now 25 pounds lighter, in the best shape of my life, and have intense boot camps every weekday morning.

Biography:

John D. McDonald, P.E. is Smart Grid Business Development Leader for GE’s Grid Solutions business. John has 46 years of experience in the electric utility transmission and distribution industry. John received his B.S.E.E. and M.S.E.E. degrees from Purdue University, and an M.B.A. degree from the University of California-Berkeley. John is a Life Fellow of IEEE, CIGRE Distinguished Member, Past President of the IEEE Power & Energy Society (PES), VP for Technical Activities for the US National Committee (USNC) of CIGRE, and Past Chair of the IEEE PES Substations Committee. John received the 2009 Outstanding Electrical and Computer Engineer Award from Purdue University. John has published one hundred fifty papers and articles, has co-authored five books and has one US patent.