by Claudio Silva, Efacec, Portugal, and Christoph Brunner, it4power, Switzerland

The approach chosen is global as it considers at the same time, the increased need of flexibilities in the system (mainly improved balance of supply and demand in electricity markets, provision of existing and future system services and allowance of a dynamic control of electricity flows) and the sources of flexibilities (RES, demand-response, grid and new storages).

The chosen global approach addresses all system requirements to capture the synergies proposed by the different solutions in order to avoid stand-alone solutions that might be less efficient in terms of overall efficiency.

Within a specific project task, work has been undertaken to demonstrate an optimized IEC 61850 engineering process. Based on the work done by the ENTSO-E IEC 61850 task force, that defined a profile for high-level function definitions, steps are being taken to better understand what is needed at design and specification phases to achieve an improved and sustainable engineering process. The outcome of this process defined a set of requirements to the standard that are provided though IEC 61850-6-100.

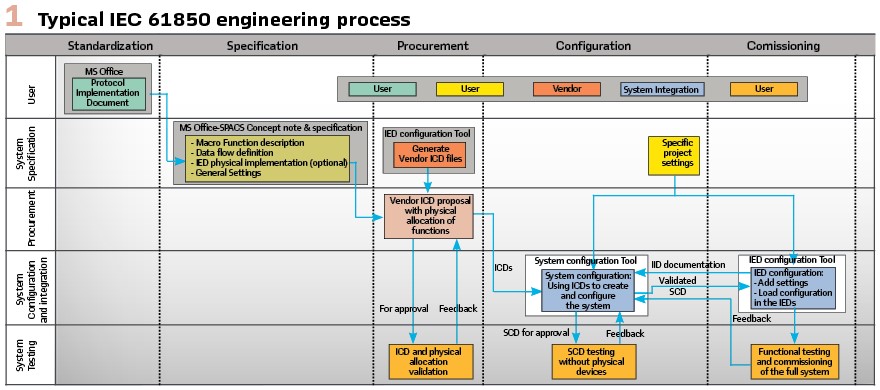

This project brings to light the advantages of using a full top-down IEC 61850 engineering process. Covering all steps of a project, considering a design phase, a specification phase, a selection and procurement phase, a system configuration phase and finally an installation phase, SCL files are used to exchange information, making user requirements transparent to vendors and IED capabilities transparent to users, while increasing the overall efficiency and quality of the process.

These enhancements will make possible for users to create vendor independent system specifications with integrated signal flow between functions and an optional physical allocation of functions to IEDs using the concept of virtual IEDs.

The inclusion of this information on a machine-readable format leverages tools to provide users an enhanced decision-making process since it provides a standard method for comparing a specification to IED vendor offers and an enhanced configuration process with the possibility of automatically generating device configurations based on the mapping of a specification (virtual) IED to a real IED.

This article describes the current work developed within the OSMOSE project, detailing the current results of the different work areas. In particular, a comparison between the standard engineering process and the OSMOSE proposed engineering process and a description of the interoperability testing procedures that will allow to validate that the proposed changes to the engineering process provide the expected interoperability and efficiency improvements.

This validation is done in a multivendor ecosystem, with one Interoperability Specification Tool (IST), two System Specification Tools (SST), four System Configuration Tools (SCT) and three IED Configuration Tools (ICT), with different vendors providing the required tools, devices and simulation platform.

The IEC 61850 Engineering Process

Current Engineering Process: A PAC engineering process defines the required steps to come from a general system specification to an engineered and working substation. This is part of the day-to-day work of a lot of TSOs and DSOs around the world. It is then very important for the users of this process that it is as efficient as possible and compatible with IEDs from all vendors to guarantee an optimal integration of multi-vendor systems.

Current engineering process is the result of putting together the desired concept within the existing constraints. Multiple actors take part in this process, as depicted in Figure 1, and produce, in an asynchronous way, a set of information where only some of them are machine-processable. This creates a time-consuming process, with little room for automation and a substantial risk of interpretation errors between parties.

While the principal engineering process was described in IEC 61850 initially, there was a large focus only on the engineering of the communication of information between IEDs of different vendors. Many details were not specified and left to the interpretation of the tool vendors. This resulted in a lack of interoperability, linked to the content and interpretation of the different SCL files in tools, and efficiency. Some of the issues were fixed with the latest revision of IEC 61850-6 (Edition 2.1, published in 2018) but still, gaps remained. Those gaps are visible in the (1) lack of support for a concept of templates and libraries in order to support standardization efforts in utilities, (2) impossibility to define applications including information exchange already at specification independent from a future implementation with specific devices, and (3) reduced semantic interpretation of the data model of a system and of devices.

This has been recognized by the IEC TC57 working group (WG) 10 based on feedback from users including the ENTSO-E IEC 61850 task force. Therefore, within IEC TC57 / WG 10, a task force was created to address those issues in a technical report (planned publication IEC (TR) 61850-6-100) which will later lead to integration into the base standard.

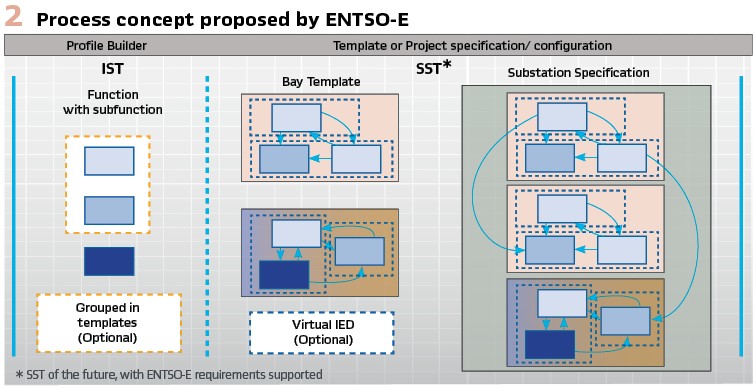

The ENTSO-E engineering process improvement proposal: The ENTSO-E IEC 61850 taskforce made a proposal to enhance the IEC 61850-6 engineering process described in IEC 61850-6 standard to make it more applicable to the design and specification phases. At the design phase of the engineering process, it was proposed to introduce a way to formally describe function and subfunctions, optionally grouped in templates, defined by an interoperability specification tool (IST), independent from a project or a device. In other words, a profiling of the IEC 61850 standard to restrict its flexibility to user requirements.

These templates would then be used at the specification phase in a system specification tool (SST). These improvements also considered the inclusion of the definition of data exchange between subfunctions. In this way, the user has the possibility to define his concept in a library of functions and subfunctions, including a predefined dataflow, which can be then instantiated in the next steps of the engineering process. Additionally, the concept of “virtual IED” is introduced, which can be seen as a preliminary physical allocation of functions and subfunctions. (Figure 2).

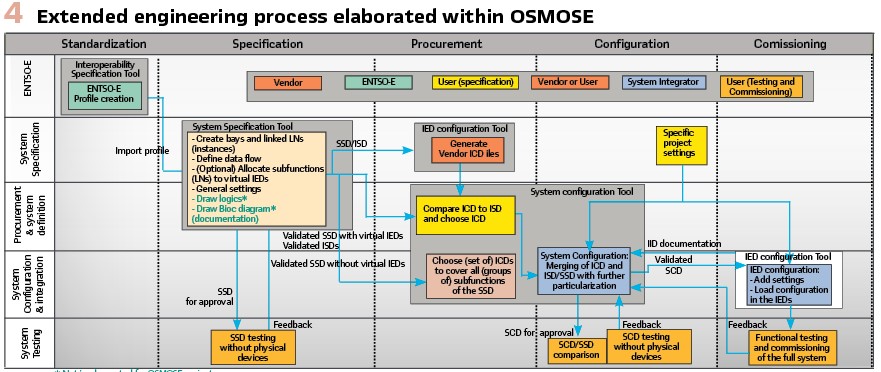

Proposed OSMOSE Engineering Process: The OSMOSE IEC 61850 taskforce merged the ENTSO-E exercise (limited to design and specification phases) with the classic IEC 61850 engineering process and added additional steps and refinements. With the goal to define a full top-down IEC 61850 engineering process, covering all 5 phases of a project, this taskforce proposes an engineering process exchanging machine-readable documents based on SCL between phases.

This guarantees optimal efficiency and quality, making user requirements transparent for vendors and IED capabilities transparent for users. Additionally, it makes possible for users to create vendor independent system specification, with integrated signal flow between functions and with optional physical allocation of functions to IEDs (using the virtual IED concept). Tools are then able to help the selection of IEDs, by providing a comparison between the requirements of the user and the capabilities of each device.

This allows a manufacturer to supply an ICD matching the user requirements instead of a generic one. This evolution of the process makes possible to automate a significant part of the configuration of the system based on the data exchange defined at the specification phase to produce a complete dataflow at IED level without human interaction. (Figure 4).

Comparison between the classic and the enhanced engineering process

In the following sections, a comparison is made between similar tasks in the classic process, as depicted in Figure 1, and in the OSMOSE proposed process, as depicted in Figure 4 below.

Design phase: Within the design phase, utilities typically use standard office applications to create a document that contains a library of signals and functions used by the utility and its mapping to IEC 61850 data model. This produces a non-standard document with very low efficiency since it cannot be automatically processed by a machine.

The OSMOSE taskforce proposes for this phase the use of the IST developed by ENTSO-E. This tool contains TSO specifications for data models and communications services and incorporates IEC 61850 data models for easy mapping of the ENTSO-E requirements with the IEC 61850 standard. It generates a machine-readable file based on SCL that contains the utility profile containing all signals and functions used by the utility, as well as extensions allowing definition of an application and required inputs of this application.

This change enables knowledge share through utilities exchanges and IEC 61850 model database incorporated for usage. It is an enabler for new utilities that are introducing IEC 61850 since it eases the creation of their own specification with reduced effort and, when standardized, IST functions can be integrated in other IEC 61850 engineering tools, making this process available for all users.

Specification Phase: During the specification phase, utilities also use standard office tools to produce a SPACS concepts and specifications for tendering the system. There is typically a big effort associated with the creation of these documents easily confirmed by the dimension of such documents. As in the previous phase, the outputs generated are not machine-readable which lead to very inefficient and error-prone processes.

By using a vendor independent system specification tool (SST), as proposed by OSMOSE, utilities can produce a system specification description (SSD) file, based on SCL, that reuses the application templates defined on the previous phase to design the system by defining data exchange between functions independently of any vendor device implementation. This strongly typed language reduces the risk of bad interpretation by a vendor of the requirements for the system. It additionally provides an independent physical allocation design, allowing the user to only define the concept and boosts the ability to re-use it in the future across different kind of tools in a fully interoperable way.

It facilitates also the inclusion of testing tools at this stage. With a complete system specification in a machine-readable format, the SSD file can be used by testing tools to simulate the entire system. It allows an early identification of errors, long before the project execution, improving the global efficiency of the process.

Procurement / Comparison Phase: When the utility is looking for devices that fit their requirements, they need to evaluate manually each vendor ICD file. A typical process assumes that vendors propose ICD files based on the written specifications and the utility needs to validate it and check if the proposition meets the requirements. The suitability of each device to the requirements depends a lot on the correct interpretation of the requirements by the vendors.

Within OSMOSE, this phase is organized around the comparison of the same ICD files as before but with an IED Specification Description (ISD). The vendor is then able to specialize the ICD to match the user specification by adapting the data model and providing the context of usage of the device with the template electrical topology. This comparison can be done automatically, with software tools being able to catalogue multiple ICD files and identifying which one matches the requirements better. It provides, with less effort, a bigger efficiency in identifying the correct device to use in each project. As proposed, this step can boost standardization in offer analysis documents and provides more flexibility for users to choose the solution they want.

System Configuration Phase: The following two steps are already a commonplace in IEC 61850 projects engineering. However, with the application of machine-readable format files in the previous steps, the effort required to achieve a similar result is highly reduced.

Systems are configured by using ICD files from device vendors and an SCD file is generated as an output. In the classic engineering process, this is typically the first step where SCL files are manipulated by a tool. In the OSMOSE proposed process, some of the engineering was already done on the previous steps, with the definition of functions, allocation of functions to devices and definition of the data exchange between functions, and thanks to specialized ICD which fulfil SSD description, an SCT should be able to automatically map the device to the specification and generate the dataflow between devices based on data exchange requirements. Additionally, once the configuration is done, users can perform a validation/comparison of the SCD file with the original SSD to check for any deviations. These deviations can then be corrected on the SCD file or used to update the original system specification to ensure that future projects no longer incur in the same issues.

IEC Configuration and Commissioning Phase: As described in the previous phase, this is a standard task in current IEC 61850 engineering process. Within the OSMOSE proposed engineering process, the steps to be taken are the same. SCD files are imported in ICT to finalize the configuration and perform a full test of the system. Even though the required effort will be similar to the classic process, it will be less likely to incur errors since validations have been performed starting from the first phases of the process and more parts of the process can be automated. Additionally, errors detected during the commissioning can serve as an input for an SSD update to avoid making the same mistakes in the future.

Demonstrator

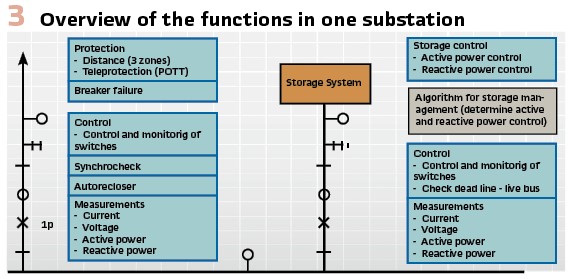

Application Scenario: For validating the enhancements discussed before, a demonstrator was defined. The scenario selected consists of the usage of energy storage to optimize the load on a line. For that, on each side of the line, storage equipment is available. An overview of the functions is shown in Figure 3. Distance protection will be applied with a teleprotection scheme or with tunneling of GOOSE messages between two substations.

Engineering Process: To configure the demonstrator substations, the enhanced engineering process described before was used. Functions and subfunctions were defined using the IST. The created SCL files were then used in an SST as a starting point to create the specification for one substation including data exchange between functions, preconfigure parameter values and associate functions in a global user application. Also, if functions are allocated to virtual IEDs, the ISD files were created for the various IEDs. An SSD file was then generated, as per IEC 61850-6 specification, which included the process section and virtual signal flow and an ISD file, for each IED specification, as per current discussion in IEC TC 57/WG 10.

The project design is then made using an SCT as defined in IEC 61850. IEDs were selected and pre-engineered based on the SSD or ISD files in the ICTs, adapting the default ICD to reflect the specification and integrating the electrical part managed by each device. The SSD was then imported into the SCT, that the adapted ICD files, would match the IEDs to the specification thanks to the electrical part of the ICD. Then the SCT automatically generated the data flow between devices based on the specified data exchange. The information exchange with the other substation is handled using the SED file between the tools as described in IEC 61850.

The detailed configuration of the IEDs is done using an ICT. The ICT imports the SCD file and completes the configuration by keeping interactions with the SCT to a minimum since a standard top-down process was followed. The final SCD file was then generated and compared with the original SSD to ensure that the configuration matched the original specification.

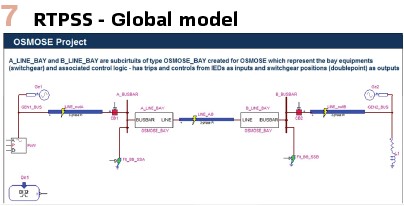

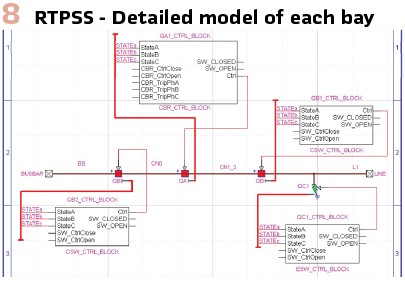

Setup: The demonstrator has been installed in a laboratory environment using a real-time platform, designed for testing PAC systems. This testing platform is based on a Real-Time Power System Simulator (RTPSS), capable of simulating power systems interacting with real IEDs in the denominated Hardware-in-the-Loop (HIL) tests. (see Figure 5).

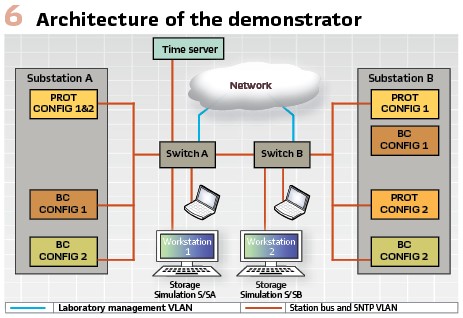

The demonstrator considers two substations, A and B, and two different configurations. The first using the “virtual IEDs” concept and the second without. The IEDs for these substations have been integrated in a communication network which also includes a time server, two workstation, two communication switches, one HMI and laptops with IED configuration tools. (Figure 6).

In this network, two VLANs have been configured for simulating the communication between two substations. The IEDs represented in the figure have different colors, meaning they are from different manufacturers (each manufacturer represented by a color). This setup allows implementing both configurations considered for the demonstrator.

For this project, the developed system model considered the two substations, the transmission line connecting them and the adjacent transmission lines. For each substation, all switchgear has been modelled. Since process bus was not considered for the demonstrator, the connections between the RTPSS and the IEDs are hardwired. (see Figures 7 and 8).

Conclusions and Future Work

The engineering process, as it is proposed by the OSMOSE IEC 61850 taskforce aims at improving engineering efficiency and quality by building further on the enhancements proposed by ENTSO-E and existent SCL language. The result is a generic process which can be applied to specify and engineer any system supporting SCL. With work still in progress, the OSMOSE taskforce has already identified the necessary SCL extensions required to execute the proposed engineering process, and the OSMOSE profile enhancements and extensions necessary to resolve existent gaps. These have been integrated in the participating engineering tools and a demonstrator setup had been put in place. Additionally, the OSMOSE taskforce is working closely with IEC TC 57/WG 10 to provide inputs for standardization, in particular in IEC 61850-6-100 and IEC 61850-7-4.

We are aware that in order to make this process widely implemented it is still necessary that the market embraces the idea that supporting interoperability is a selling point, not a constraint, and the enhanced process is not new, just a digitalization of the existing process. Users also need to start to see the benefits of this process on the long term. They need to be willing to adopt this engineering process, knowing that the impact on the company may be extensive. And finally, we need IEC 61850 standards to provide the qualitative framework that allows the market to implement this enhanced engineering process.

The project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 773406

Biographies:

Claudio Silva is a Lead Product Manager for Software and Systems within the Protection, Control and Automation division at Efacec. With 15 years of experience in R&D and Product Management, he participated in different projects related with Power Systems PAC, with a strong focus in systems engineering and tool interoperability. He holds a BSc in Informatics Engineering from Faculdade de Engenharia da Universidade do Porto and advanced courses in Computer Science. He is an active participant in Cigre B5 WGs and a member of IEC TC57 WG15.

Ricardo Cartaxo Project Researcher of R&D Nester since 2013. Prior to joining R&D Nester, Ricardo Cartaxo worked at Efacec (from 1989 to 2000), in the automation systems department and at REN (from 2000 to 2013), also in the automation systems department. Ricardo holds a degree in Electrical and Computer Engineering (power systems area) from Instituto Superior Técnico, Lisbon, and an MSc from the same institution. His main areas of interest include control and automation systems, communication networks for power systems, and related international standards, such as IEC 61850.

Thomas Sterckx is working as an IEC 61850 expert at the secondary systems department of Elia. He has a master’s degree in electro-mechanical engineering and has more than 10 years of experience in substation secondary systems in different roles at Engie Fabricom and Elia. He is involved in the implementation of IEC61850 in the Elia substations, focusing on domains of implementation standards, the engineering process and engineering tools. As a WG10 member, he follows closely the evolution of the IEC61850 standard in the interest of the current and future needs of Elia.

Camille Bloch is IEC 61850 System Experienced Principal Technical Expert of Relay Application Centre of Excellence at Schneider Electric Energy Management Business after multiple carrier steps within R&D at ALSTOM and AREVA. He is member of IEC TC57 WG10 and the French national mirror committee. As member of IEC TC57 WG10, he is specialized in IEC 61850 system engineering process, and editor of standards IEC 61850-6 and IEC 61850-7-7. Camille is convenor of the new CIGRE WG B5.68 and member of Linux Foundation for Energy (LFEnergy) CoMPAS project.

Christoph Brunner is the President of his own independent consulting company it4power LLC based in Switzerland. He has over 25 years of experience with knowledge across several areas within the Utility Industry and of technologies from the Automation Industry. He has worked as a project manager at ABB Switzerland Ltd in the area of Power Technology Products in Zurich / Switzerland where he was responsible for the process close communication architecture of the automation system. He is Convener of WG 10 of the IEC TC57 and is a member of WG 17, 18 and 19 of IEC TC 57. He is member of IEEE-PES and IEEE-SA. He is an IEEE Fellow and is active in several working groups of the IEEE-PSRC and a member of the PSRC main committee and the subcommittee H. He is advisor to the board of the UCA international Users group.