By Birkir Heimisson, Landsnet, Iceland

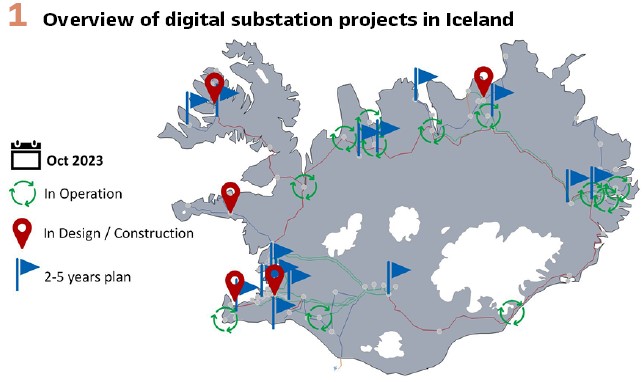

LANDSNET the national transmission system operator in Iceland, is in the process of rolling out multiple fully Digital Substations on its transmission network. LANDSNET owns and operates on total 85 substations and 3526 km of transmission lines and cables. By end of 2023 LANDSNET will have 12 sites with fully digital substation solutions. The new digital substations will cover a voltage range from 220kV down to 66kV. Overview of Icelandic Grid and these projects can be seen in Figure 1.

In the last decade LANDSNET has explored the potentials of digitalization with e.g. implementations of simple station bus applications only for the purpose of communicating signals from control and protection (C&P) equipment via IEC 61850 client/server communication (MMS) to a protocol conversion gateways, where signals would be converted to IEC 60870-5-104 for communication to the Supervisory Control and Data Acquisition (SCADA) system of the control room. LANDSNET has also during the last decade been a forerunner in implementation of Wide-Area-Monitoring and Control with associated Smart-Grid development.

Following this experience, LANDSNET made a strategic decision in 2019, to apply fully digital, multi-vendor and IEC 61850 based protection and control system to all its new-build and refurbished substations. Low power instrument transformers (LPIT) are required for new-build projects, where most of them are capacitive based sensors and Rogowski coil, as all the ongoing projects are gas insulated switchgear (GIS). The strategic decision followed, an important transmission network investment decision to strengthen LANDSNET’s existing transmission grid to accommodate more renewable generation from hydropower and geothermal generators. To achieve this large-scale grid modernization of the transmission network, following criteria were set for refurbished and new build substations.

1. Building of substations that reduce TOTEX investment costs

2. Faster building and refurbishment of substations

3. Create provisions for more offsite testing and faster commissioning on-site

4. Increase operational flexibility and reliability

5. Improve sustainability and use less materials in substations, through smaller housing, reduction in use of copper by 80% and reduction in use of oil and gas

6. Improved personal safety with less hazardous electrical circuits

Technical Requirements & Top-Down Engineering

LANDSNET started with the engineering design and deployment of its first projects, in 2019. For the first projects the tender documents and requirements were lacking sufficient clarity and details regarding specification of IEC 61850 data model and engineering design. These first specification only required that the Digital Substation should be compliant with to IEC 61850 edition 2, leaving the interpretation and large degree of freedom in the implementation to be provided by the system-integrators.

In the old specification, LANDSNET did not have any specific requirements regarding the IEC 61850, e.g. details of device and data models, requirements for Top-Down engineering design process during creation of system configuration description (SCD) file.

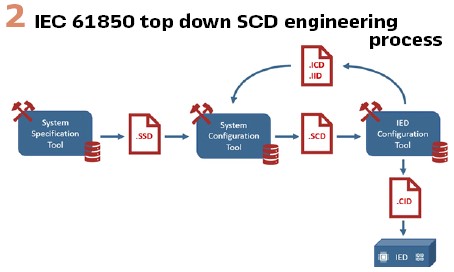

As LANDSNET and the contractor/system-integrators were implementing these as their first large scale Digital Substations projects, it was a steep learning curve for all players. The first implementations were more bespoke and less standardized. For example, most projects started with a bottom-up design, which led to complexities while engineering a large substation with multi-vendor IEDs. Eventually LANDSNET decided to adopt and require top-down design, to avoid such complexities in future applications and greatly improve standardization.

Following the first projects, LANDSNET consulted and cooperated with industry experts with previous experience with Digital Substations engineering design and with vendors to discuss various requirements, in order to achieve a truly standardized engineering design and to unlock the full benefits of IEC 61850 standard. LANDSNET thus started the process of translating its conventional protection and control requirements to IEC 61850 standard and created system specific requirements which included:

1. Detailed data models for each function within the substation, and corresponding IED model

2. Specific requirements for SCD files

3. Functional and communication requirements for IEDs and Switches to support full top-down engineering and ensure compatibility with the communication architecture such as required number of network ports, redundancy requirements, PTP compatibility and cybersecurity requirements

4. An implementation guide for multi-vendor based Digital Substations to standardize implementation across different contractors implementing Digital Substations

The new process for requirement engineering enabling top-down design is shown Figure 2. The system specification description (SSD) for each function and bay type is still under development and is currently being enhanced as LANDSNET is applying Digital Substation technology to different bay types. In the meantime, the necessary engineering requirements and design meetings are provided for the system integrators to standardize engineering design process using a system configuration tool (SCT) of their choice, which includes:

- Logical node mapping

- Substation section

- Standardized network architecture

- Standardized signal-list including

- References to IEC 61850 semantic data model

- Minimum use of generic inputs such as GAPC & GGIO

- Automatic generation of IEC 60870-5-104 addresses

- The implementation guide includes:

- IP addressing structure for all communicating devices in the substation

- Sampled Values (SV) & GOOSE naming and MAC-Address rules

- Naming structure of IED, dataset, GOOSE and report control blocks

- COMTRADE naming

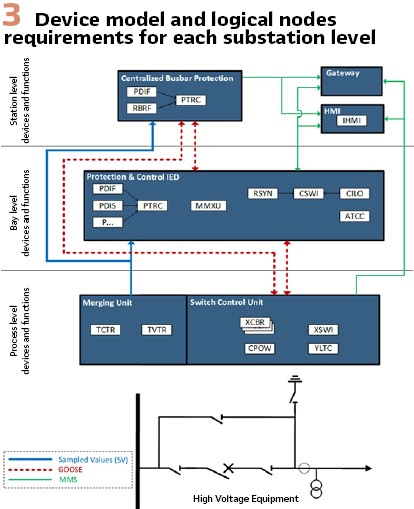

An example of the need of detailed specifications is the requirement to follow the IEC 61850 data model also requires the allocation of logical nodes (LN) in appropriated devices according to IEC 61850-5 device model. A simplified diagram of this can be seen in Figure 3.

There we can see that LN for switchgear, such as XCBR, XSWI are supposed to be in the switch control units (SCU) and interlock nodes, i.e. CILO in the protection and control IEDs. The proper design should not allow for multiple instances in different devices for such LNs.

It is crucial that such design considerations need to be a part of the specification and design process and are provided to the IED suppliers and system integrators as part of procurement, tender and selection process.

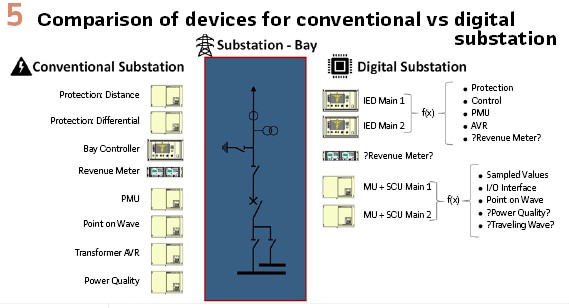

The digitalization of the power system brings in need thought process when it comes to C&P functionality. The industry has for many years treated each functionality as standalone box/device and multiple device approach has been adopted to facilitate functional redundancy. However, IEC 61850 introduces the concept of functional design and that digitalization and definition of data models enabling different functions the idea is that the physical device can run multiple functions constrained only by its processing power and communication interface capabilities. The comparison between C&P equipment for both conventional substation and Digital Substation for one bay can be seen in Figure 5.

LANDSNET categorizes the substation after its importance in the grid operation and where critical grid nodes require Main 1 and Main 2 redundant C&P devices while the lesser critical nodes of the network only require a single protection system i.e. Main 1. With digitalization and the trend of combining functions into IEDs, LANDSNET revaluated its protection philosophy, and concluded it has the more feasible option to run all protection functions redundantly on both Main 1 and Main 2 IEDs. The Main 1 and Main 2 IEDs are also required to be from two different vendors for to avoid single type of failure during operation.

Figure 5 also shows few functions as question mark, as the industry has not solved or standardized logical representations on those functions yet and/or the standard developments are not available as commercial solutions. One of the key requirements is revenue metering. LANDSNET is currently discussing this topic within the industry; as to whether utilities and regulators still require standalone revenue meter per bay or if we will see further development in that area as the source of metering is coming from the merging unit (MU) itself and the process of integrating the energy could be integrated as function within any other device. There is a similar consideration regarding power quality measurements and travelling wave fault location especially with implementation of Low Power Instrument Transformers (LPITs). It could be a possibility to integrate such functionalities requiring higher sampling rates within the MUs or any other process interface unit, instead of publishing SVs with extremely high data rate on to the process bus, which then requires higher bandwidth and extra network traffic filtering mechanisms.

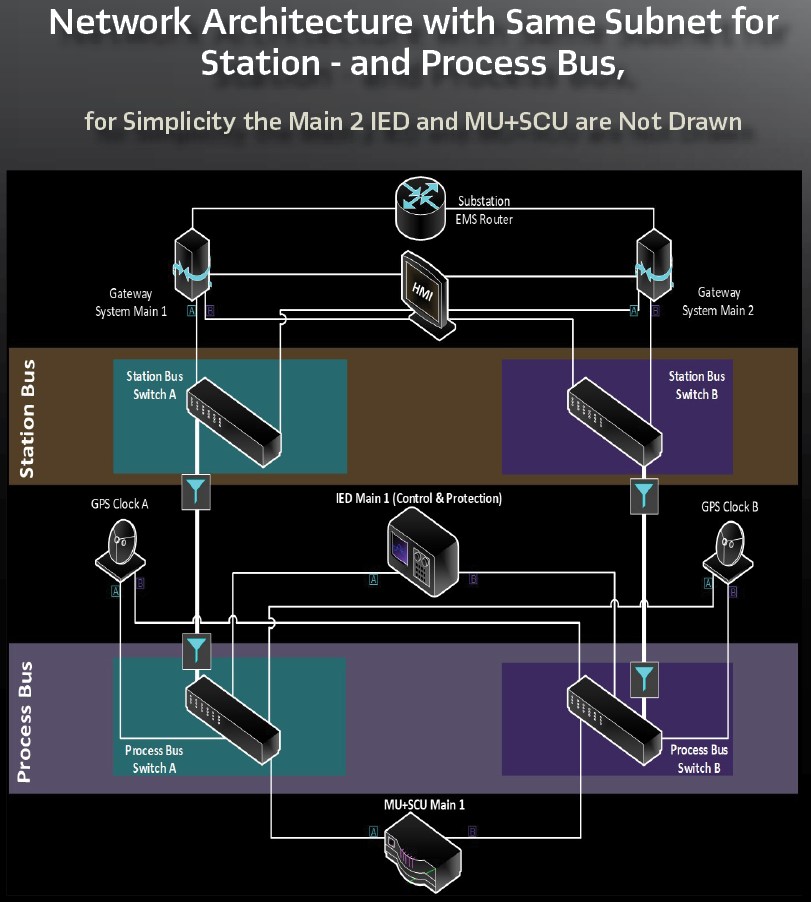

Network Architecture and Time-synchronization

At the onset of LANDNSET’s Digital Substations journey the communication network architecture of Digital Substations was still in evolution with different concepts and design. System Integrators were given the flexibility to implement any system architecture they deemed satisfying the functional and C&P availability requirements. This however led to implementation of bespoke architectures, some with application of redundancy protocols, some with non-redundant station bus and process bus comprised of coupling between Parallel Redundancy Protocol (PRP) and High-Speed Redundancy (HSR) protocol, with various degrees of complexity and bandwidth constraints.

LANDSNET then determined, this posed serious risk to the long-term performance of the substations and posed serious challenges during testing and commissioning. A decision was then made to standardize PRP redundancy protocol for both station- and process bus in its system architecture design, due to its easy configurability and scalability, and to keep uniform implementation across all its future implementations.

Furthermore, for the first projects, the commonly utilized architecture with a physically segregated station- and process-bus was implemented. The drawbacks of such architecture are the number of ports per device and increased number of parallel connected switches needed to connect all devices, especially for larger substations. Also, for larger substation there is need for network traffic filtering in order to efficiently manage large amount of network traffic, through application of destination MAC-Address and/or VLAN filtering. This was especially crucial to filter SV to avoid overloading of individual device links which were usually still limited to 100 Mbps. The need for filtering also rises from the fact that most MU today both for conventional and LPIT publish 2 SV streams, one satisfying the measurements standard 0.2S and other for protection standard 5P. As the substations get larger and with requirement for Main 1 and Main 2 MUs each publishing at least two streams the number of SV streams on the process bus require filtering to manage network traffic and ensure high availability and reliability of C&P functions.

LANDSNET has now standardized its’ network architecture to a single subnet for complete substation network, and the concepts of station- and process bus are virtualized with the use of Destination MAC-Address filtering, or VLANs. Filtering is designed to allow only SV flow on the network ports where they are needed, like the concept of the point-to-point wiring in conventional substations. Other traffic like GOOSE, PTP, MMS, etc, are not filtered, but with option to be added later if needed. This kind of architecture reduces the number of ports and switches needed but requires the network engineering to achieve the optimal traffic management. This architecture in shown on page 38. The figure still includes physical switches for station- and process bus with filtered coupling links between them, but with proper filtering design the switches could possibly be reduced, with complete virtualized station- and process bus.

The time synchronization with PTP is the heartbeat of Digital Substations. Currently LANDSNET has required redundant GPS/GLONASS-disciplined grand master (GM)clocks with PTP Profile IEC 61850-9-3 in each substation with the future options also of distributing PTP over the wide-area-communication network (WAN) as a primary grandmaster time source.

Testing and Commissioning of Digital Substations

The drive for digital has made LANDSNET focus on automation and optimization on all aspects of Digital Substation delivery process from design to testing and commissioning. Digital Substations unlock vast potentials for automation and optimization that increase operational flexibility and reduce the time and effort required for on-site commissioning, and future operation and maintenance of digital assets. In order to automate and optimize Digital Substation process LANDSNET invested in automated creation of standardized signal lists, IED configurations, protection settings (.XRIO) and C&P test plans.

The testing of Digital Substations is one of most important benefits of the digitalization of substations, as it makes it possible to conduct near complete testing of all the C&P functions and whole system right up to the primary interface during the factory acceptance test (FAT). Thus, allowing for 85% of the tests to be completed offline and greatly reducing the time and effort onsite during the site acceptance test (SAT) and official commissioning of the substation. On top of that, it allows for new improved approach during maintenance testing and remote testing and support. Following are testing of the complete C&P systems:

1. SCD verification and system configuration validation

2. Network testing, e.g. stress, filtering and redundancy

3. Time synchronization testing

4. Signal testing, all signals simulated and then automatically validated from event lists from HMI & Control Room SCADA

5. Automated Interlocking tests

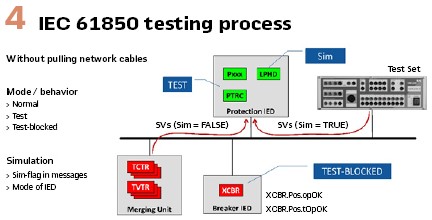

6. All C&P functions testing with use of IEC 61850 test mode and sim-flag (see Figure 4)

The aforementioned test methodology offers the advantage of conducting outage-less maintenance when having redundant Main 1 and Main 2 control and protection IEDs. LANDSNET already has made use of this in the simulation and test mode features by fully testing the Main 1 system, while having Main 2 protecting the real system. The system in operation test realizes “outage-less maintenance” benefit of fully digital substations.

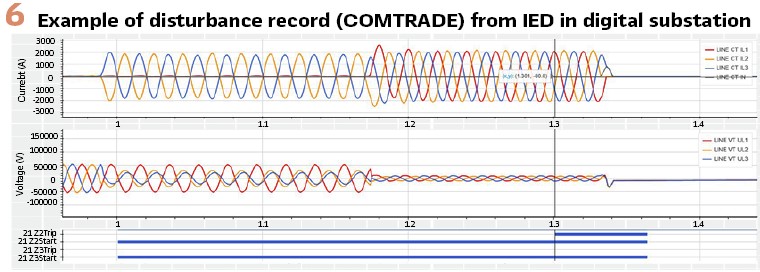

In the last 2-3 years there have been multiple disturbances on the network requiring the protection operation of the new Digital Substations, none of the events have resulted in mis-operation. A disturbance records in Figure 6, shows an event of a line fault on a radial 66kV transmission line, which is connected to a digital GIS substation with LPITs. This disturbance is a phase-to-phase fault, evolving into 3-phase fault, being picked up on distance protection zone 2 with 300 ms pickup time. The trip time is measured at 39 ms, i.e. time from the trip being triggered at the IED, GOOSE being sent to SCU and circuit breaker to open. It can be noted that at the time of this disturbance, the line differential protection for this transmission line was not yet in operation. Expected pickup times of such fault would be significantly less if similar fault would occur today.

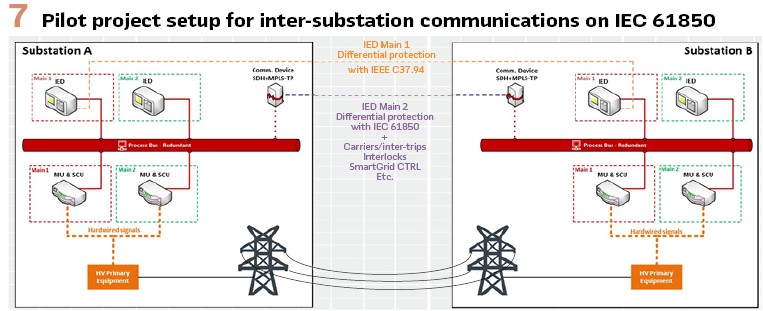

On the Horizon: Looking out into the future, LANDSNET is working towards the concept of Digital Transmission System. That is, communicating IEC 61850 data between multiple substations within the grid. That will enable more flexibility in any control, protection or smart grid development in the future. The same system can be enabler for wide area distribution of common time sync reference for the whole power grid. A drawing of the pilot setup can be seen in Figure 7, where line differential protection will still be operated on conventional serial IEEE C37.94 between Main 1 IEDs, while Main 2 IEDs will operate line differential on IEC 61850 with communication of SVs and GOOSE between the substations.

Wrap up: The experience gathered so far by LANDSNET, proves that Digital Substations are feasible on transmission and by extension on distribution networks for protection, automation, and control (PAC) applications. However, as in the case of any emerging technology and evolving standard, it is always a work in progress. It has indeed been a quick transition for the company to start roll out of multi-vendor Digital Substations on a large scale. The key lesson learned from the journey is to define utility own specification and requirements before tendering out Digital Substation projects.

It is also not necessary to have everything perfect at first, but to simply consider the key outcomes from the experience around the world at the onset of rolling out Digital Substations at a large scale. LANDSNET has already identified gaps in interoperability of different standards and vendor implementations, and they are continuously communicating this to the relevant parties. LANDSNET works in collaboration with its service providers, industry experts and vendors, to enable seamless delivery of Digital Substations. The short experience of the operation of these substations has been good so far and without any major issues, and even though it has been a challenging start with implementing new technology at this scale in middle of a global pandemic, the decision is still undisputed, and LANDSNET is optimistic for the operation of these flexible digital assets for the future to come. They will reduce the carbon footprint, improve self-supervision of assets, introduce automatic and remote testing options and increased flexibility to any enhancements in control, protection and smart-grid functionality.

Biography:

Birkir Heimisson – is Specialist in Digital and Smart-Grid Development at Landsnet. He Received his B.Sc. in Electrical Engineering from University of Iceland in 2011 & M.Sc in Electric Power Engineering from Chalmers University in 2014. He joined Landsnet (TSO of Iceland) as a system operator in 2014. Together with system operation, he led the Smart-grid development with focus on Wide-Area-Measurements and Control. Additionally, Heimisson was work-package leader for Landsnet in EU Horizon 2020 MIGRATE project. In 2019, he moved to research and development, where he focuses on Digital Substation implementation based on IEC 61850 and Smart-Grid Development.