Relay Testing – Testing Devices in the 1990s (Part 3)

by Walter Schossig, Germany, and Thomas Schossig, OMICRON electronics GmbH, Austria

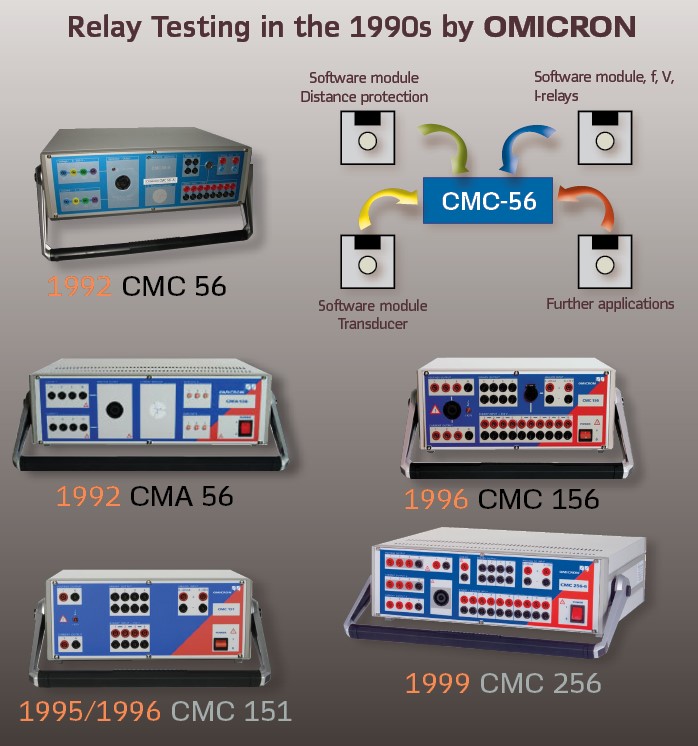

his article shall finalize our reports on the 1990s and the entire series on protection testing devices. The 90s have been known for a wide range of test sets. Further developments as well as new releases pushed the market continuously.

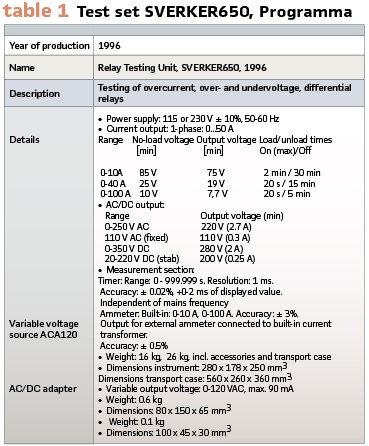

Let’s start with the well-known SVERKER series. With SVERKER750 already in 1993, a multi-functional protection test set was presented. Another device, the SVERKER650 was released in 1996. To test single phase overcurrent, overvoltage and directional relays it was developed to be robust and portable. HARALD and SVERKER650 have been produced at Programma in Sweden. They came with a suitcase (Figure 1). A voltage accessory (ACA120) allowed the testing of directional relays. The voltage was received from the 110-VAC output of the test set (see Figure 2 and Table 1).

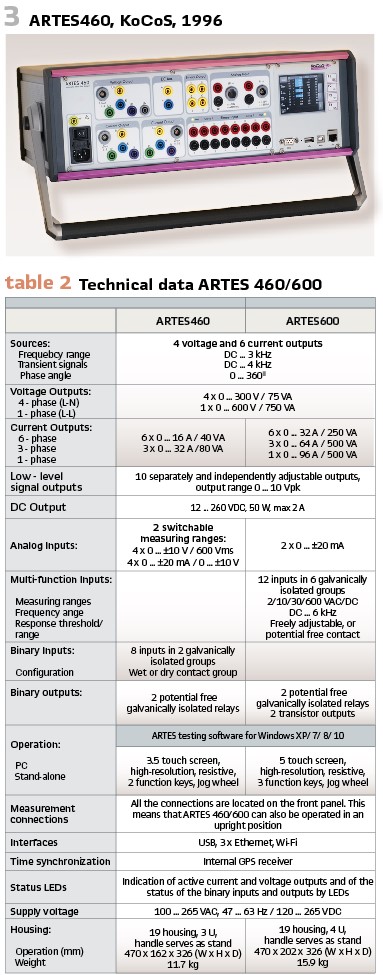

In 1996 the German company KoCoS released the 3rd generation of their protection testing devices. It was called ARTES460 and could be operated for the first time with MS Windows based software.

Four voltage outputs and six current outputs have been protected against overload and short circuit (Figure 3).

The ARTES600 Switching in parallel allowed test currents of up to 96 A (single phase) (Table 2).

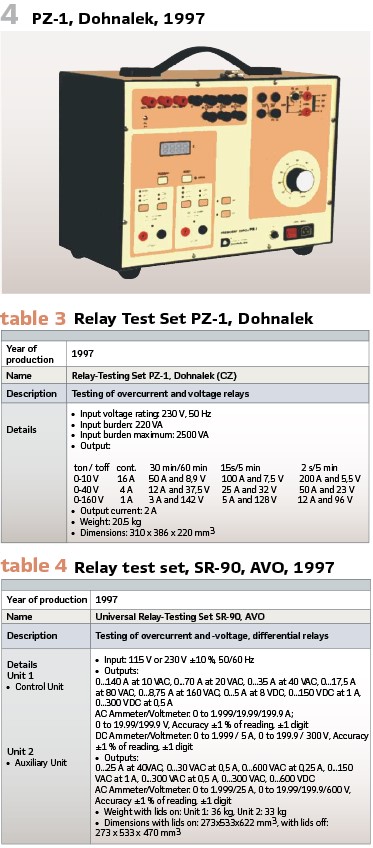

ZPA Trutnov (CZ) was mentioned as relay vendor already. The company Dohnalek originated from ZPA Trutnov and produced the relay test set PZ-1 (Figure 4 and table 3).

Portable test equipment PZ-1 is used as a source of variable current or voltage and for time delay measurement of protection relay.

The PZ-1 consisted of variable auto-transformer, supply transformer and timer. The whole apparatus was housed in a metal case with removable cover of the rear panel. It allowed measurements in the horizontal or vertical position.

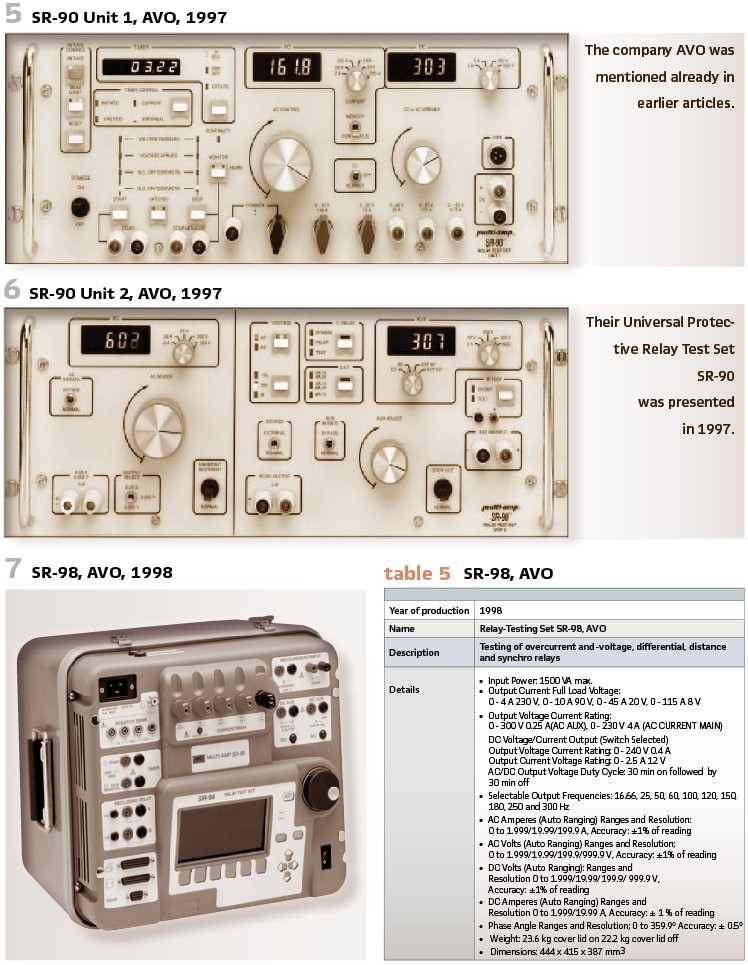

The company AVO was mentioned already in earlier articles. Their Universal Protective Relay Test Set SR-90 was presented in 1997 (“Multi-Amp®”) See Figure 5, Figure 6, and table 4.

The SR-90 Universal Test Set was a multipurpose, two-piece test set. It could test electromechanical and solid-state protective relays accurately and efficiently. It was versatile and field portable. With its power (1.4 kVA) it was good for testing of any protective device requiring up to 420 A. The model was designed so the main control section (unit 1) and the auxiliary section (unit 2) could be used independently for testing simple protective devices,

The successor was the SR-98, released in 1998. Table 5 and Figure 7 show the details. It provided powerful testing capabilities. For example, the AC current output could provide 16.66 or 25 Hz for testing light rail transit system relays. In addition, the AC current could be programmed to provide 2nd, 3rd and 5th harmonic currents for testing harmonic restraint elements in transformer differential relays.

Mainly for testing circuit breakers but also overload relays AVO released in 1999 the test set CB-832 (table 6, Figure 8).

In 1989 the French company COTEL was founded. In 1998 the first sales of digital test system HEXAN was released

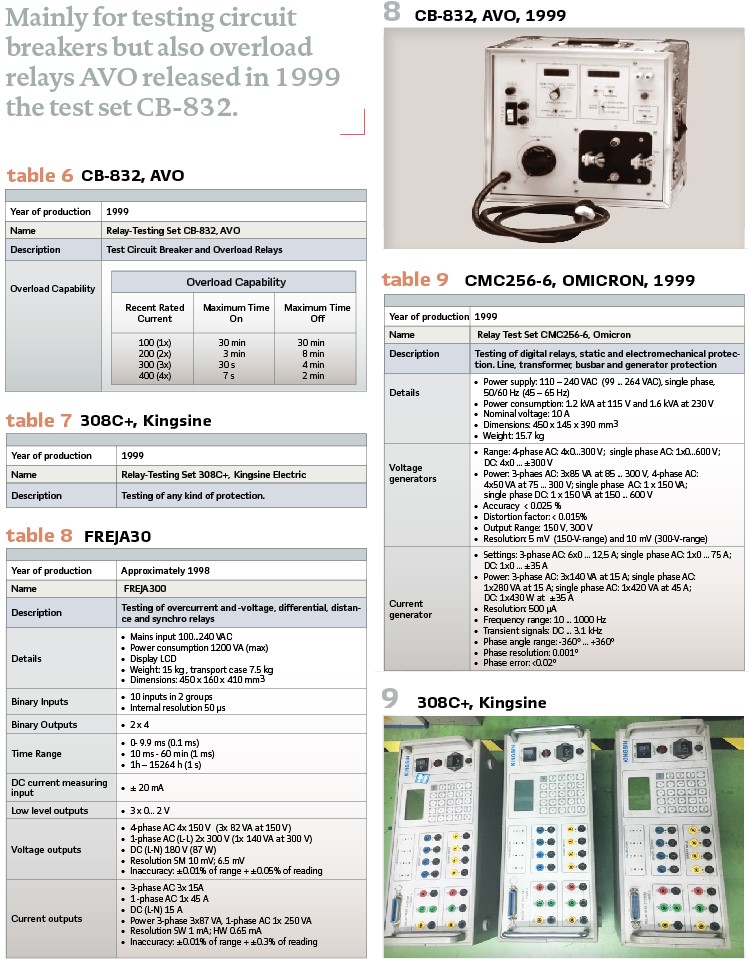

The Chinese vendor Kingsine is also active in the protection testing market since 1999.

The first relay test set with microprocessor in China was model 308C +. This relay test set was the first generation of multifunctional relay test set by KINGSINE and adopts the user-friendly local panel operation and received great popularity in the China market (Table 7 and Figure 9).

Back to Programma. A three-phase test set, called FREJA300, could be presented in 1997 for the first time (Table 8 and Figure 10).

The high power of generators allowed the testing of several electromechanical protection devices. If there was more power necessary or in case of differential protection more than three currents have been needed the amplifier CA3 was available.

In 1999, OMICRON presented the CMC256-6. It came with a lot of functionalities, unique measurement capabilities and allowed the recording of transient signals (see Figure 11 and table 9).

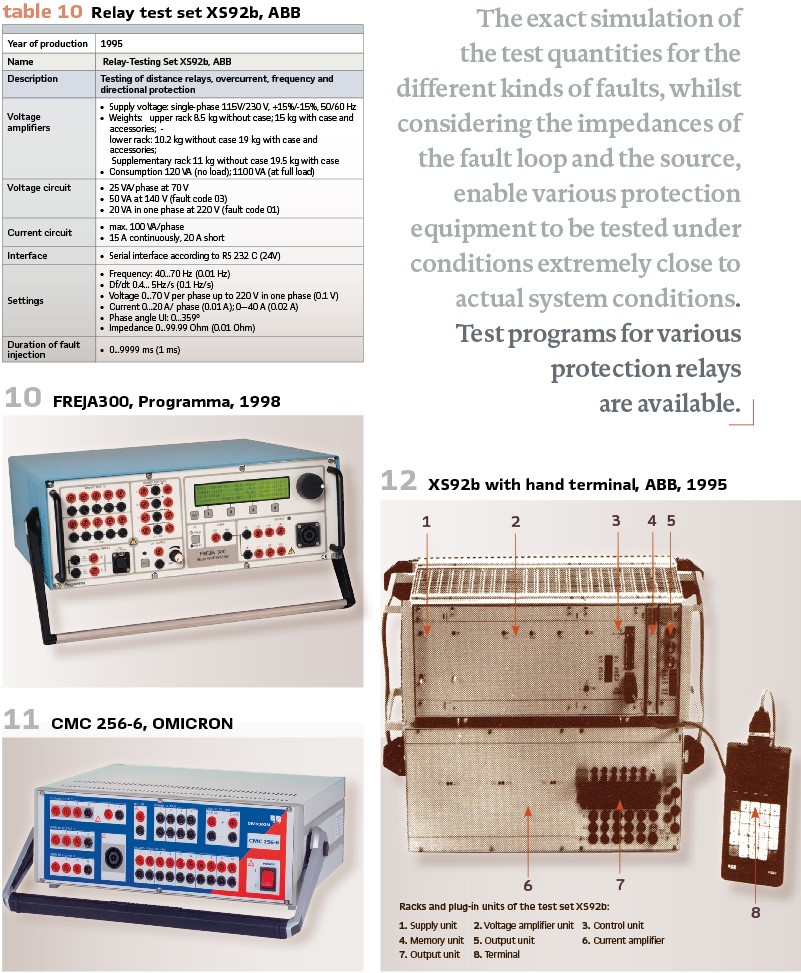

BBC presented already in 1985 a protection testing solution. This was revised in 1995 and released as XS92b by ABB. It was computer controlled and came in 2 suitcases- one for the test set and one for the accessories. The 16-bit microprocessor allowed dynamic and static testing within wide ranges, whilst selecting current, voltage, phase-angle and impedance as parameters.for easy testing of Line, Generator, Transformer, Busbar and Circuit Breaker back-up. An upgrading kit for XS92a was available (Figure 12 table 10).

The parameters current, voltage or impedance can be set in amplitude and phase-angle and their entry determines the output quantities, three-phase voltages and three-phase currents for the basic version.

The exact simulation of the test quantities for the different kinds of faults, whilst considering the impedances of the fault loop and the source, enable various protection equipment to be tested under conditions extremely close to actual system conditions.

Since the test quantities are first calculated and then transformed into an analog signal in a D/A converter, they are unaffected by spurious signals (e.g. harmonics) contained in the supply voltage. The values of the settings can be checked by simply calling them up on a PC or onto a two-line liquid crystal display utilizing the hand terminal (option). The user can write testing sequences which correspond to his own circumstances and store them, or retrieve them, from the memory unit type YS92 (option).

Test programs for various protection relays are available. For routine testing this resulted in a great deal of time saving.

walter.schossig@pacw.org www.walter-schossig.de

thomas.schossig@omicronenergy.com

Biographies:

Walter Schossig (VDE) was born in Arnsdorf (now Czech Republic) in 1941. He studied electrical engineering in Zittau (Germany), and joined a utility in the former Eastern Germany. After the German reunion the utility was renamed as TEAG, Thueringer Energie AG in Erfurt. There he received his Master’s degree and worked as a protection engineer until his retirement. He was a member of many study groups and associations. He is an active member of the working group “Medium Voltage Relaying” at the German VDE. He is the author of several papers, guidelines and the book “Netzschutztechnik

[Power System Protection]”. He works on a chronicle about the history of electricity supply, with emphasis on protection and control.Thomas Schossig (IEEE) received his master’s degree in electrical engineering at the Technical University of Ilmenau (Germany) in 1998. He worked as a project engineer for control systems and as a team leader for protective relaying at VA TECH SAT in Germany from 1998 until 2005.

In 2006 he joined OMICRON as a product manager for substation communication products. He is author of several papers and a member of standardization WGs.