by Christopher Pritchard, and Georgii Tishenin, OMICRON electronics, Austria, and

Scott Cooper, OMICRON electronics, USA

While the basic premise of transformer differential protection is straightforward, numerous features are employed in relay algorithms to compensate for challenges presented by the transformer differential application. As a result, developing appropriate test quantities and properly quantifying results can be challenging with traditional functional differential testing.

Challenges in Traditional Functional Testing

A traditional functional test assures that all measurements and derived quantities are measured and calculated accurately and that the overall relay hardware including inputs and outputs are functioning. Therefore, the test quantities of a traditional functional test are defined as a sequence of steady state or phasor values. This type of testing is performed throughout the life cycle of a relay. During commissioning this type of test can further assure whether threshold and time elements are set according to the given settings from engineering. The following describes typical tests and their challenges:

Pickup Testing

Even the simple three phase pickup test, when tested manually, requires the test designer to calculate the nominal operating current amplitude, or tap, for each winding. The currents on one winding are increased from zero until the relay trips. The pickup current value is then converted back to per unit and compared to the setpoint.

Slope Testing

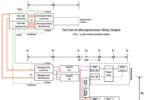

For differential characteristic tests of the slope region, the proper phase shift is determined from the transformer three-line diagram. For three phase tests, balanced quantities are applied to two or more current inputs which simulate balanced load, then the currents on one side are incrementally increased until the differential element operates. For tests of a single differential phase, calculation of realistic through fault current phasors must be calculated. Evaluating the results of slope characteristic tests is not straightforward as there is significant variation in the restraint current calculation between differential relay manufacturers. The maximum per-unit phase current, minimum per unit phase current, the average per unit phase current, the sum of the per unit phase currents, or some other calculation altogether are used. Some differential relays incorporate a reference winding in the restraint calculation that can be set or calculated automatically. If the simulation of single phase faults is desired, the relay’s method of zero sequence elimination must also be considered. To simplify this process dedicated software tools, exist that can calculate the required steady state quantities by using an internal transformer model. The software module can then directly inject the quantities, measure back the pick-up and trip signals and make an assessment on the steady state accuracy. But also, these tools have their limitations when the relay applies adaptive characteristics or work in the time domain instead of the frequency domain, as we will describe in the following sections.

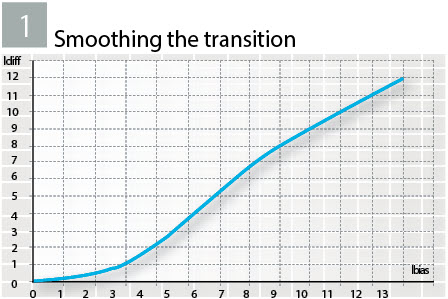

To further complicate the testing, modern relays incorporate a number of additional characteristic features. Some relays incorporate cubic splines to smooth the transition between slopes 1 and 2. (see Figure 1).

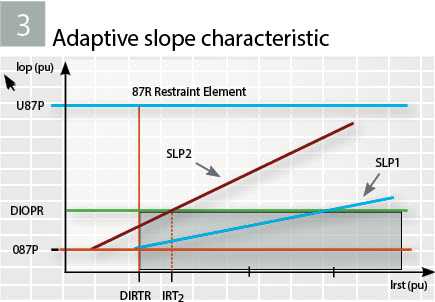

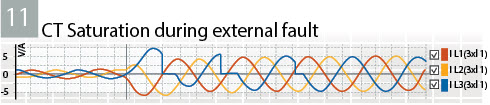

Testing in the cubic spline region requires additional calculations. Another common feature is an adaptive slope characteristic. This is applied to restraint against external faults that might cause current transformer (CT) saturation on one transformer side. An external fault initially causes a current increase only in the restraining quantity. (Figure 3).

When functional testing the differential element, the slope applied is determined by pre-fault current inputs. To test the high security slope characteristic, pre-fault state duration and pre-fault current amplitude are coordinated with the relay settings and fixed relay parameters.

Inrush & Overexcitation Blocking

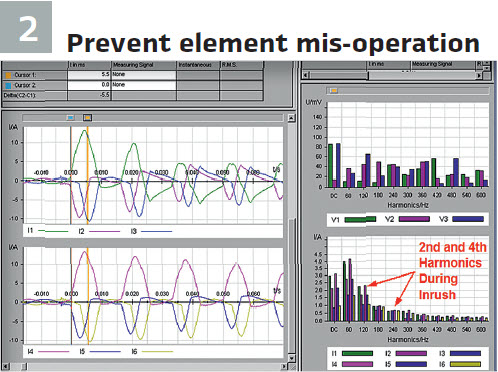

To restrain the differential element during magnetizing inrush most relays use both the second and fourth harmonic content of the calculated phase differential currents. (Figure 2).

In addition, some relays incorporate additional features to prevent differential element mis-operation due to circuit breaker closing angle. There are a variety of schemes in use. The most common is perhaps using the highest measured harmonic in any phase to restrain all phases. However, some devices use cross phase averaging, where the average even harmonic content in all phases are used to restrain the differential. A completely different inrush blocking algorithm analyses the current signals in the time domain. If the current dwells close to zero and is unipolar it is considered an inrush condition. This method has better sensitivity on new core materials with reduced loss but therefore low 2nd harmonic content.

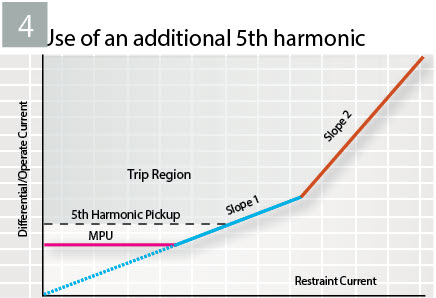

In generator step up transformer applications, an additional 5th harmonic may be used to either restrain or desensitize the transformer differential element against overexcitation. (Figure 4).

Restricted Earth Fault

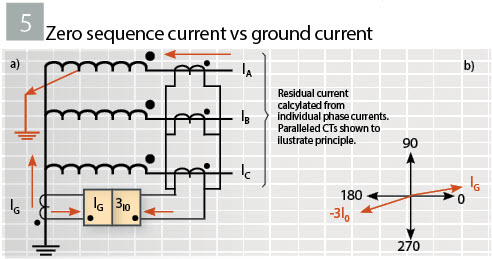

Related to the transformer differential element, restricted earth fault elements that better protect the neutral end of wye connected transformer windings are steadily gaining acceptance. In these schemes, the calculated zero sequence current from the wye winding phase currents is compared to the measured ground current. Functional testing of these schemes requires the test designer to properly calculate phase current phasors for internal and external faults to check proper operation. Logic is also incorporated to create operating windows and provide protection when the transformer is energized from one side only. (Figure 5 a/b).

Is this Testing Adequate?

Even after surmounting the many challenges of functional testing, the fundamental question of settings adequacy remains mostly unanswered. If the relay does not operate fast, secure and dependably during the power system event, the goal of the protection system is not met. Therefore, the goal for protection testing must be to make sure the protection system is doing its job.

System-based Testing of Transformer Differential Protection

A new testing approach that can reduce the challenges and ensure that the settings are adequate is called system-based testing. The idea is simple: if we want to make sure that the relay trips for an internal fault, we just simulate an internal fault to test the response of the relay. If we want to make sure the relay is secure against tripping for through faults, we just simulate through faults and verify the relay does not operate.

Thus, a system-based testing solution calculates the testing quantities within a sub-transient power system simulation, directly outputs the signals with an amplifier, measures the response and assesses the result.

Transformer Simulation

When defining a system-based test case, we do not think about the element or algorithm under test, but about the power system incidents this element is supposed to act on, for example:

- Faults external to the protected zone

- Faults internal to the protected zone

- Turn-to turn faults

- Turn-to ground faults

- Inrush during energization

- Transformer overexcitation due to overvoltage

- CTs saturation and ratio errors

The electromagnetic transient (EMT) simulation of these incidents is one of the cornerstones for a system-based testing solution. The reliability of a simulation result depends on accurate input data. To make the testing tool practical for technicians and engineers in the field we must find a solution that yields numerically stable and reliable results and apply heuristics, where data is not available.

The Transformer Model

Relevant power system scenarios include low-frequency transient events such as faults, and low-frequency non-linear phenomena such as inrushes and overexcitation.

High frequency phenomena in the power system are not relevant to the transformer protection relay due to internal algorithms and the cut-off frequency of anti-aliasing hardware filters. Therefore low-frequency transformer models are suitable for system-based transformer protection testing.

The more physical, geometrically based and detailed the transformer model is, the more accurate simulation results will be. However, parameter availability imposes the major constraint on the accuracy of the simulation results in the field. From a field technician perspective, the main source of information is the transformer nameplate. Information about core material and dimensions, number of winding turns, and geometry of the winding is not normally available. Thus, it is important that the model can be parametrized from nameplate data using reasonable heuristics which are based on guidelines provided in international standards and by expert working groups.

The mutually coupled coils model that is used in the described solution was proposed by Brandwajn and Dommel and offers a reasonable compromise between precision and parameter detail. The same principle is utilized in various free and commercial EMT simulation tools.

External Faults

The fault current contribution to an external phase fault, mainly depends on the positive sequence impedance of the transformer, which can be derived from the short circuit voltage on the nameplate. However, already the simulation of ground faults, requires reasonable zero-sequence short-circuit impedances for the transformer, that are not always available on the nameplate. The zero-sequence impedance is influenced by the core type, vector group, presence of compensation winding and neutral grounding. The Figure on page 46 shows how these factors affect the zero-sequence equivalent circuit of a two-winding transformer. In the figure subscripts P, S, M, N, C denote primary, secondary, magnetizing, neutral and compensation respectively.

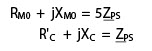

The effect of a core type and compensation winding on transformer zero-sequence impedance can be estimated using heuristics. Accordingly, system-based testing solution heuristically estimates unknown impedances RM0+jXM0 and R’C+jXC, based on a transformer positive-sequence short-circuit impedance ZPS:

Internal Faults

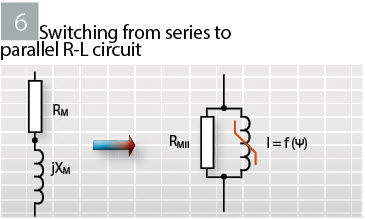

For the simulation of internal transformer faults, the system-based testing solution relies on a widely accepted method. The method extends an original mutually-coupled coils transformer model, splitting the faulted coil into two sub-coils in case of turn-to-ground faults and into three sub-coils in case of turn-to-turn faults, therefore allowing to insert a branch with a fault resistance RF to newly introduced terminals between the sub-coils. (see Figure 7).

Determining the short-circuit impedance of the split sub-coils requires knowledge of the inductive leakage factors, which again are not specified by a transformer nameplate. To estimate inductive leakage factors, detailed transformer geometrical data would be required. Since the data is not commonly accessible for relay protection engineers, we are left to rely on heuristic estimations of inductive leakage factors. Keeping our use case in mind, the most challenging scenario for the sensitivity of a restricted earth fault protection function are faults close to the neutral with just a few short-circuited turns and high fault resistance. In such a scenario, the principle of proportionality plays a higher role than principle of leakage. In other words, a contribution of fault and winding resistance to the equivalent short-circuit impedance is higher than a contribution of leakage inductance. Therefore, different inductive leakage factor heuristics yield similar simulation results for many test scenarios.

Saturating Core

All differential relays must incorporate features to provide security during magnetizing inrush and transformer overexcitation, both sources of significant differential current during these events. To achieve realistic simulated waveforms for these phenomena, the non-linear saturation characteristic of the transformer core must be simulated. Therefore, an iterative approach for inclusion of non-linear inductors into the solution is utilized.

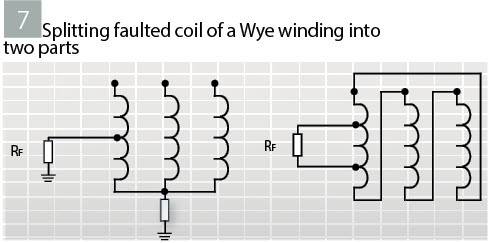

To simulate the non-linear transformer core, the system-based testing solution takes winding resistances and magnetizing branch out of the mutually-coupled transformer coils model and transforms the magnetizing branches from series R-L circuits to parallel R-L circuits with non-linear inductor (see Figure 6).

For a core-type transformer with concentric windings it is recommended to place the non-linear inductor across a coil closest to the core. The saturation of yokes and unwound limbs (for a five-limb transformer) in the transformer model are neglected as a reasonable estimation of their saturation characteristics requires detailed knowledge of transformer design parameters or results of non-standard transformer tests. The advantage of using only three non-linear inductances per transformer includes a better simulation performance and simpler parametrization, compared to more sophisticated non-linear transformer models.

For scenarios with residual flux (or remanence) the testing solution uses a non-linear hysteretic inductor model based on the principles of EMTP Type-96, which is widely accepted in power system simulations.

Setting up and Executing a System-based Test

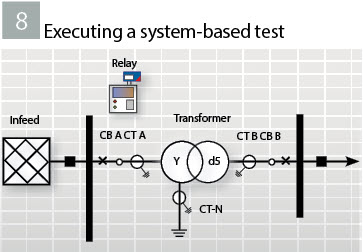

While all these details of the simulation are daunting, they are taken care of by the modelling in the software. Compared to functional testing, the test setup is much simpler. Starting from a standard power transformer topology, only the CT ratios and the transformer nameplate data must be entered: (see Figure 8).

- Vector group

- Rated voltages

- Rated power

- Short circuit voltage / impedance

- No-load current

- Core-type

The parameters for the saturating core are set automatically to typical values according to heuristic estimation of magnetization characteristic parameters and usually do not have to be adapted.

Test Cases

Defining a system-based test document requires some rethinking of existing testing procedures. For example, instead of defining a 2nd harmonic content, we simulate the energization of the power transformer at various closing angles. Instead of defining a differential & restraining current, we simulate through faults and internal differential zone faults. All these scenarios can be defined within a single-line diagram of the transformer and the surrounding power system.

From a systematic standpoint, a test document starts with a metering check, followed by test cases for stability. The differential relay is not supposed to trip for normal load current or faults on the buses, outside of the differential zone.

It may happen, that the overcurrent element trips with some time delay for outside faults. The fault can be dragged from a toolbar in the software and dropped on the bus.

To test the differential trip, the fault can also be dropped on the power transformer. For a turn-to-ground fault close to the starpoint (<5%) a differential element might not be sensitive enough, therefore a REF element, if applied, will pick up the fault. Same for turn-to-turn faults with both terminal close to each other, the differential element might not be sensitive enough, therefore a negative sequence element may pick up this type of fault.

To test stability during inrush both breakers are in an open state. Within the test case an event will close the breaker, which will cause an inrush condition. By changing the closing angle, the amount of inrush in each phase can be altered.

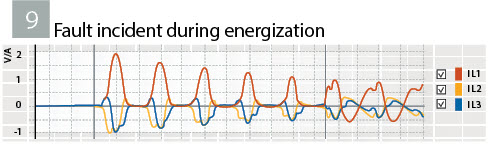

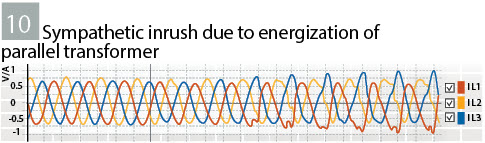

Apart from these major test cases, much more real-world scenarios can be tested e.g. sympathetic inrush, fault during inrush, external faults with CT saturation and overexcitation due to overvoltage.

Since the system-based testing solution can control multiple test sets from one PC software, three-winding transformers or REF protection can be tested without rewiring the test setup. Protection schemes for phase shifting transformers can be tested the exact same way, without adding complexity. Also, line protection systems, where the transformer is within the protected zone can be easily tested. (see Figures 9,10, 11).

Benefits & Drawbacks

The biggest benefits of the system-based test approach are the simplicity and at the same time it is making sure that the protection system is working under real world conditions.

As it is relay independent, the test document for the same type of transformer is identical, independent of the relay manufacture being used. And because it is only simulating realistic incidents, it will work for every relay algorithm improvement in the future.

On the downside, it requires some rethinking of existing testing procedures. The harmonic content of the test signal during an inrush is realistic for the type of transformer, but it cannot be set exactly below or above a certain threshold. Therefore, function testing still has its place.

So where do we invest our precious testing time and resources? If a differential relay is accurate when set to certain threshold, has been tested several times throughout its lifecycle, for example during the prequalification. But if the goal of a commissioning is to ensure that a differential relay and its engineering protect the power system and transformer, system-based testing is the right tool.

Biographies

Christopher Pritchard Dipl.-Ing. (FH) was born in Dortmund / Germany. He started his career in power as an electrical energy technician. Christopher received a diploma in Electrical Engineering at the University of Applied Science in Dortmund in 2006. He joined OMICRON electronics in 2006 where he worked in application software development in the field of testing solutions for protection and measurement systems and is now the responsible Product Manager for system-based testing solutions.

Georgii Tishenin was born in Ekaterinburg, Russia. He received the electrical engineering diploma from Ural Federal University, Russia, in 2014. Currently he works in application software development in the field of testing solutions for protection systems at OMICRON electronics in Klaus, Austria. In his role he is involved into power system modelling.

Scott Cooper has thirty years of experience in a variety of roles including substation commissioning, application Engineering, power plant operations, and technical training. He is active in the IEEE PSRC and has written numerous papers and magazine articles. He currently works as the Application and Training Engineer for OMICRON in St. Petersburg, Florida.